First core box

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

Turn over

Here you can see how we transfered the alignment from the bottom to the top. Luckily we could pick the bore of the piston rod bushing through the LP-cylinder.

Rainer

www.steamboating.de

www.steamboating.de

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

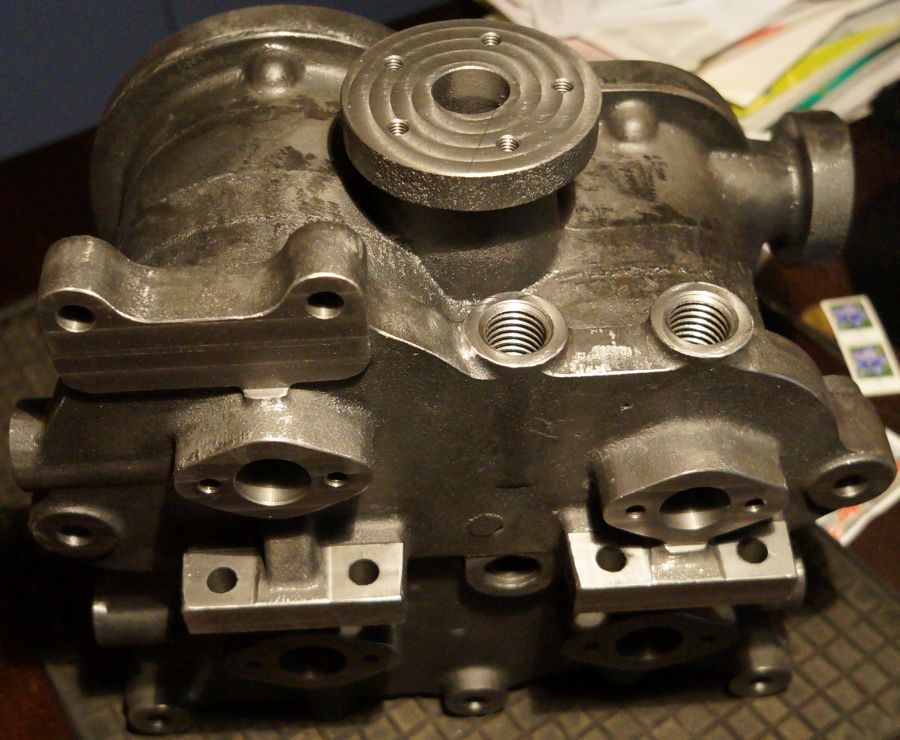

2.1 kg

That's all for this weekend.

Top surface got final machining.

In total we machined away 2.1 kg till now.

Actual cylinder weight is 19.4 kg.

All bores and threads could be machined at it's design positions.

No changes because of the casted part necessary.

Don't know how we will machine the 4 big bores - till now.

Actual this bores are circular milled 40 mm in depth.

Maybe we will find a 120 mm long mill to do it this way down to the bottom.

Still 1 mm left (on the radius).

Top surface got final machining.

In total we machined away 2.1 kg till now.

Actual cylinder weight is 19.4 kg.

All bores and threads could be machined at it's design positions.

No changes because of the casted part necessary.

Don't know how we will machine the 4 big bores - till now.

Actual this bores are circular milled 40 mm in depth.

Maybe we will find a 120 mm long mill to do it this way down to the bottom.

Still 1 mm left (on the radius).

Rainer

www.steamboating.de

www.steamboating.de

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: First core bockes

Rainer,

Very nice work as always..

Unless a large diameter cutter is used (and that is no guarantee) at that length, the cylinder is going to be tapered due to tool deflection. I would face the bottom of the cylinder/rough out the cylinder wall with a long cutter and then use an adjustable boring head and a standard boring bar to machine the cylinder wall.

-Ron

Very nice work as always..

Unless a large diameter cutter is used (and that is no guarantee) at that length, the cylinder is going to be tapered due to tool deflection. I would face the bottom of the cylinder/rough out the cylinder wall with a long cutter and then use an adjustable boring head and a standard boring bar to machine the cylinder wall.

-Ron

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

boring bar

Yes Ron, I agree with you - this would be the best way. Unfortunately I do have a 120 mm long dia. 30 mill but no small long boring bar for dia. 35 mm as needed for the HP piston valve - but let's see...DetroiTug wrote:...I would face the bottom of the cylinder/rough out the cylinder wall with a long cutter and then use an adjustable boring head and a standard boring bar to machine the cylinder wall.-Ron

Rainer

www.steamboating.de

www.steamboating.de

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

This saved my weekend

Hello Steamboaters,

for many month I am searching for drawings of the pumps of my steam engine. I "only" found in the building contract specification of the "Kaiserliche Marine" (German Imperial Navy) that it should have two single acting feedwater pumps driven by worm gear in an oil casing.

Yesterday I found in a reprint of the Lune Valley Company the "Savery Compound" engine with exactly such type of pumps. The pump arrangement is very close to what could have fitted my engine.. After googling "Savery Compound" I found pictures of the overhauling of exactly such an engine - fantastic!

Because in this period the Germans tended to copy the English steam engine designs and this is from the same era, I will redesign this pump style fitting my engine. With this I also can finish my engine base design to which the pumps are coupled. Can't tell you how happy I am with this results.

Please notice that this is only an internet link to the original picture and that all rights of this picture are reserved by "Great!Steam" from flickr

More pictures can be found here

http://www.flickr.com/photos/8517286@N02/

You can buy a casting set of the Savery by Reeves:

http://shop.ajreeves.com/launch-engine- ... -324-c.asp

But this engine replica don't has the pumps...

for many month I am searching for drawings of the pumps of my steam engine. I "only" found in the building contract specification of the "Kaiserliche Marine" (German Imperial Navy) that it should have two single acting feedwater pumps driven by worm gear in an oil casing.

Yesterday I found in a reprint of the Lune Valley Company the "Savery Compound" engine with exactly such type of pumps. The pump arrangement is very close to what could have fitted my engine.. After googling "Savery Compound" I found pictures of the overhauling of exactly such an engine - fantastic!

Because in this period the Germans tended to copy the English steam engine designs and this is from the same era, I will redesign this pump style fitting my engine. With this I also can finish my engine base design to which the pumps are coupled. Can't tell you how happy I am with this results.

Please notice that this is only an internet link to the original picture and that all rights of this picture are reserved by "Great!Steam" from flickr

More pictures can be found here

http://www.flickr.com/photos/8517286@N02/

You can buy a casting set of the Savery by Reeves:

http://shop.ajreeves.com/launch-engine- ... -324-c.asp

But this engine replica don't has the pumps...

Rainer

www.steamboating.de

www.steamboating.de

-

Kiwi Noel

- Lighting the Boiler

- Posts: 27

- Joined: Sun Jan 15, 2012 10:03 pm

- Location: Timaru, New Zealand

Re: First core bockes

Hi Rainer

Thanks for showing us what you are up to I really am enjoying seeing you progress with the build most of all is seeing how all it's all done.

Noel

Thanks for showing us what you are up to I really am enjoying seeing you progress with the build most of all is seeing how all it's all done.

Noel

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: First core bockes

Very nice pump setup, slow RPM to eliminate "pounding", and an enclosed geatbox with good lubrication of the worm. And perhaps you can buy it without expending hundreds of your labor hours to make your own, most excellent.

If the gearcase is not available, you could probably make a similar arrangement using a worm gearmotor from e-bay, available at low cost. I have seen this type of worm drive gearmotor on e-bay many times.

If the gearcase is not available, you could probably make a similar arrangement using a worm gearmotor from e-bay, available at low cost. I have seen this type of worm drive gearmotor on e-bay many times.

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

Re: First core bockes

.I don't think so because they run out of steam business recentlyfredrosse wrote:Very nice pump setup... perhaps you can buy it ...

Yes - that's what I have done already - at least to get a low cost worm gear out of it.fredrosse wrote: ... make a similar arrangement using a worm gearmotor from e-bay

To design and to build casted parts is the fun - respectively the purpose of this project - this is my engineer porn - so I promise, you will see here some casted pump casings in some month/years...

Rainer

www.steamboating.de

www.steamboating.de

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

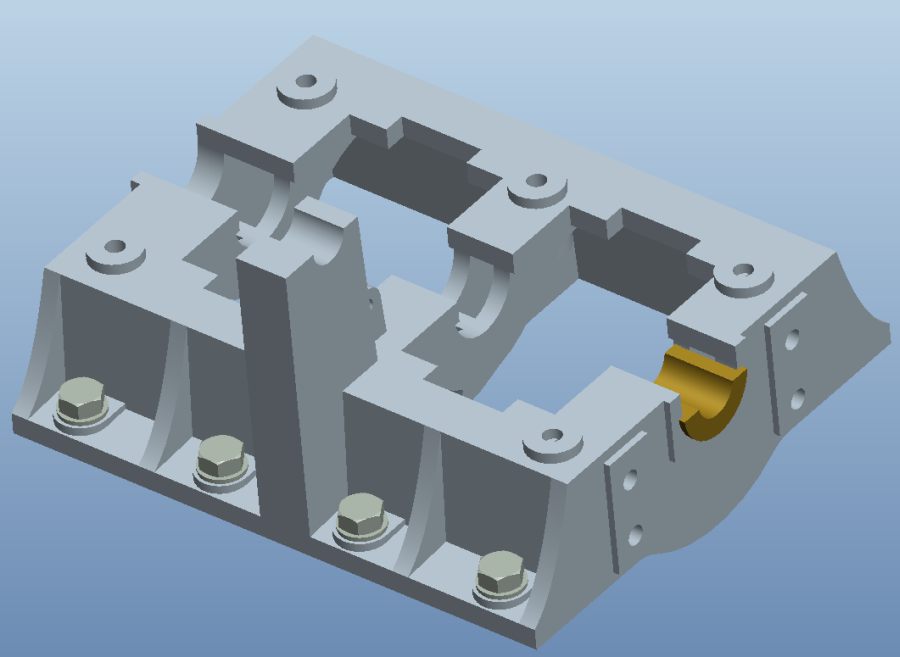

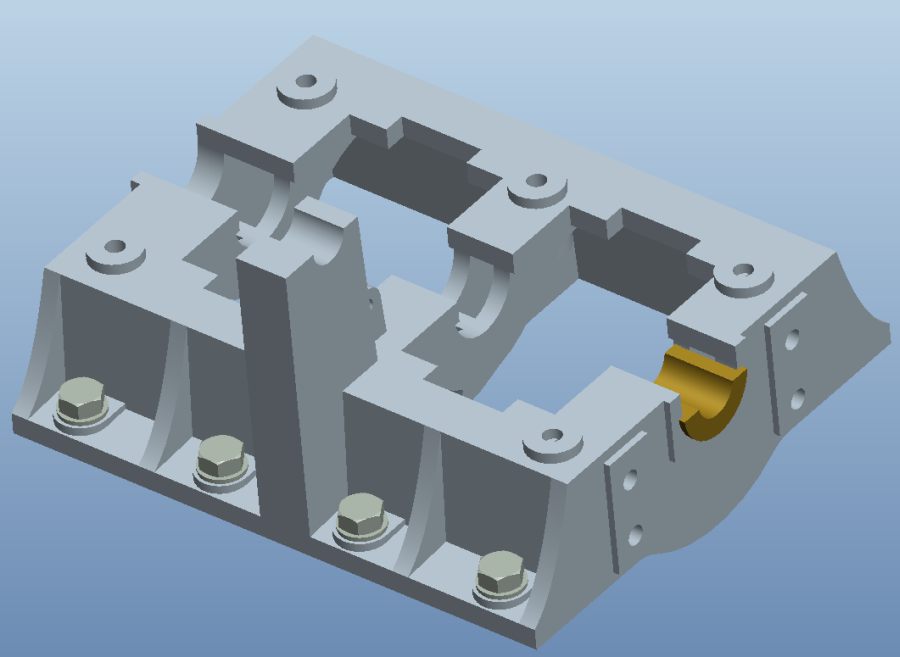

Pump flanges

Because in the moment I can not use the big CNC mill for the cylinder block at work I am redesigning the base according to the Savery design. At the right side you can already identify the flange with 4 holes ready to mount the pump assembly. Off cause the base design is not finished jet!

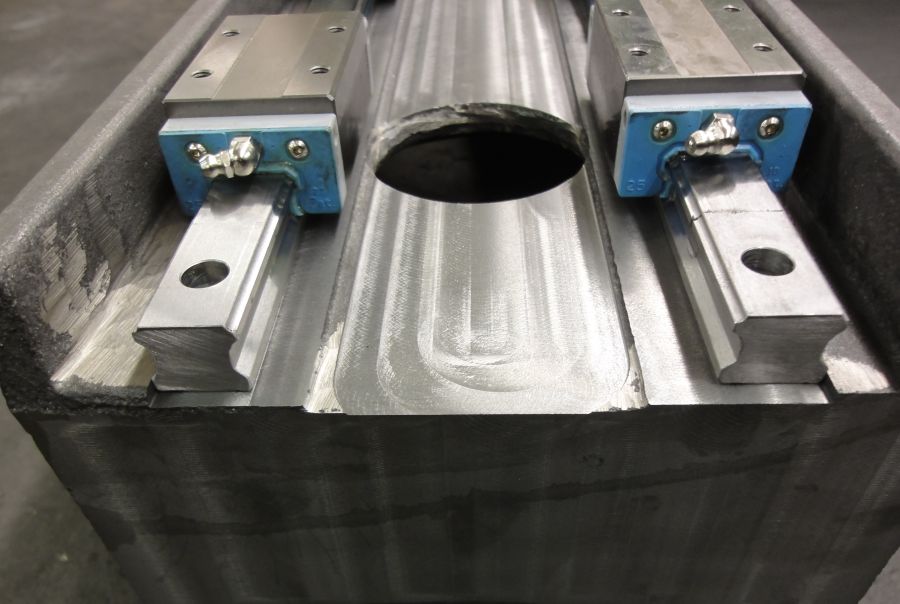

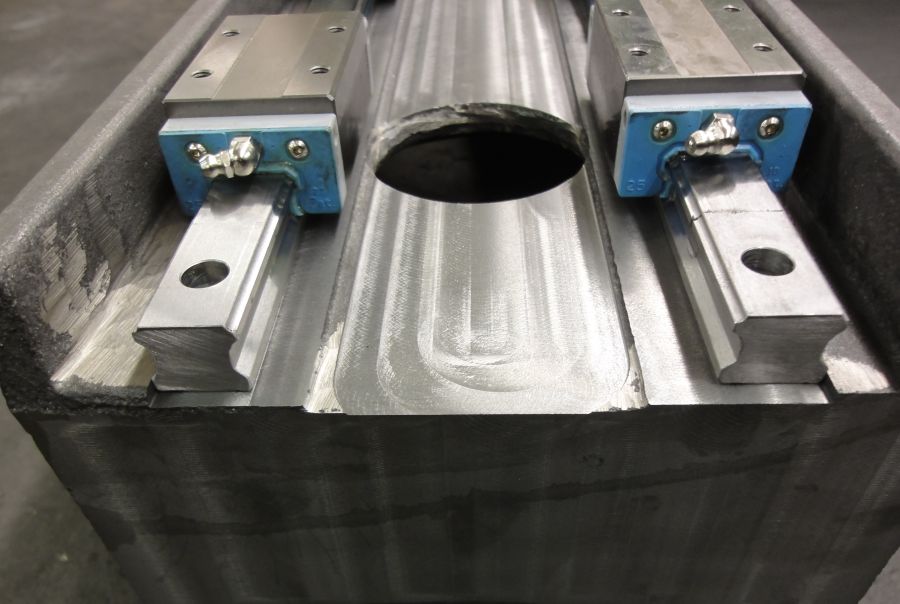

Yesterday my friend and I machined the cast iron part (designed by me) for my home-mill. It's the Z-axes with a z-travel of 500 mm. This will be driven by a DC-servo motor for cnc control via Mach3. Some days it will make me independent from other peoples machines and labor...

THK-guide

Yesterday my friend and I machined the cast iron part (designed by me) for my home-mill. It's the Z-axes with a z-travel of 500 mm. This will be driven by a DC-servo motor for cnc control via Mach3. Some days it will make me independent from other peoples machines and labor...

THK-guide

Rainer

www.steamboating.de

www.steamboating.de