Olfeldt

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Olfeldt

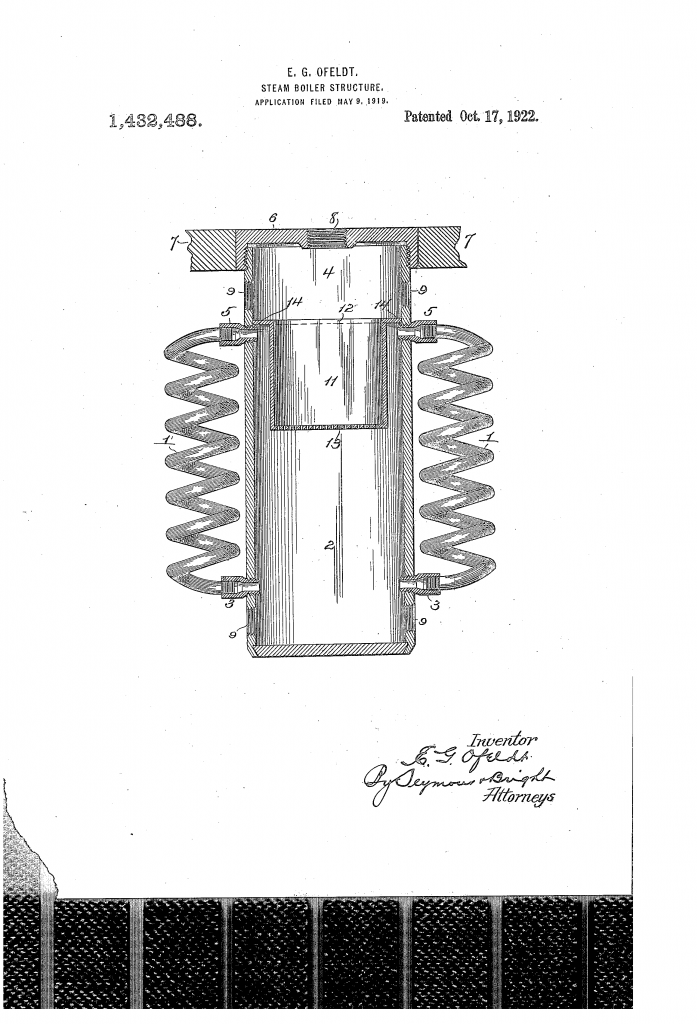

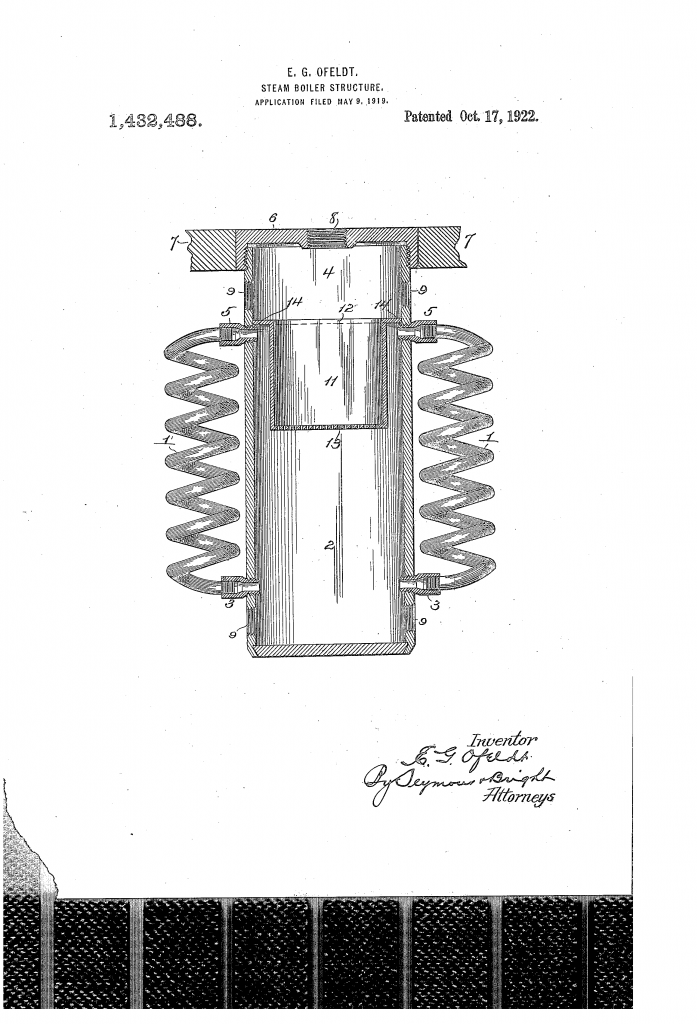

In the drawing you posted the 2 inch pipe/cap/flange is a welded assembly. The main pressure vessel has a flange welded in to mate with the 2 inch assembly. It appears that the connection could also be made with a 2 inch "thread-o-let" welded to the main pressire vessel. The 2 inch pipe could be removed for inspection and cleaning, but with much less work than installing a flanged connection.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Olfeldt

Having just assembled an Ofeldt, we looked at different ideas for attaching a steam dome to prevent carry over. A threadolet to attach the dome may not allow proper orientation of the outlets mounted in the dome on successive removals and re-installs/retightening due to deformation of the threads.

I'm not a big fan of bolting heads on a boiler. There is the issue of maintaining a seal. Also depending on the pressure and surface area of the component, there is a substantial combined force on the bolts securing it. Welding all of the seams makes them equal strength which is very high and equal maintenance which is typically zero. If internal corrosion is a concern later on, one head can be removed in minutes with a plasma arc and new head refitted in an hour or so. Much less time than dealing with something that will not seal reliably or orient properly.

-Ron

I'm not a big fan of bolting heads on a boiler. There is the issue of maintaining a seal. Also depending on the pressure and surface area of the component, there is a substantial combined force on the bolts securing it. Welding all of the seams makes them equal strength which is very high and equal maintenance which is typically zero. If internal corrosion is a concern later on, one head can be removed in minutes with a plasma arc and new head refitted in an hour or so. Much less time than dealing with something that will not seal reliably or orient properly.

-Ron

-

johnp

- Full Steam Ahead

- Posts: 242

- Joined: Mon Nov 23, 2009 6:43 pm

- Boat Name: Cardinal Queen

- Location: Richmond Hill, Ontario, Canada

Re: Olfeldt

The drawing shows a 2"dia x 4 3/4" long pipe. Could I not just extend the main steam drum by 4 3/4"? this would allow more area for penetrations.

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Olfeldt

Extending the larger drum would work better than the original design, although some extra metal and a taller boiler, probably no issue on your application.

The larger steam space above the water level is always helpful to avoid wet steam and to avoid water carry-over.

The larger steam space above the water level is always helpful to avoid wet steam and to avoid water carry-over.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Olfeldt

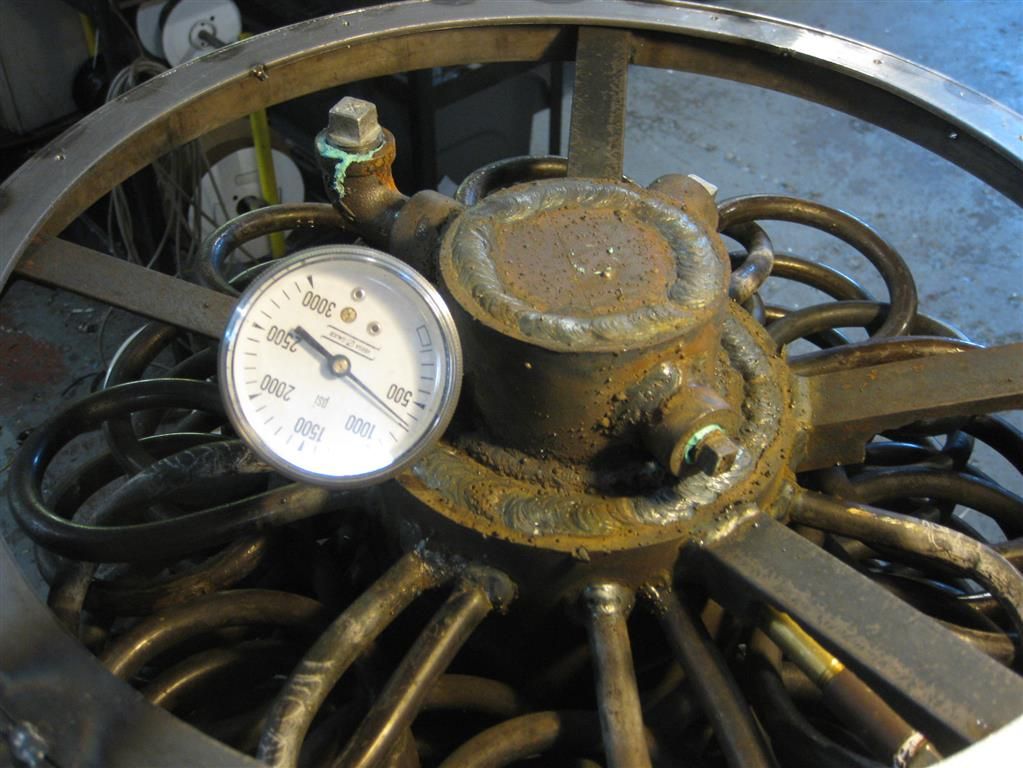

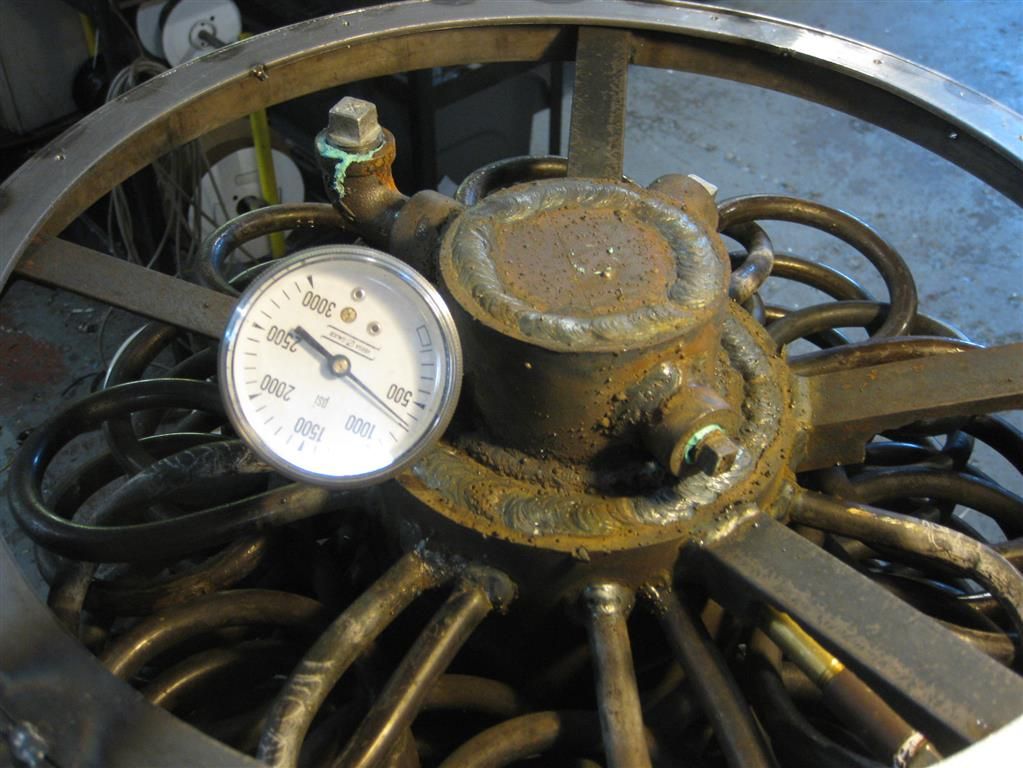

In the original Ofeldt patent there is a deflector above the tubes to direct everything out of the tubes down in to the center drum. This seems to be consistent with most Ofeldt designs I've found there is some means to direct water and steam down and only steam back up to prevent carry over. In the pic below it is shown as upside-down top hat with a screen in the bottom. Although, I think in the original design it goes down too far and would enable what it was intended to prevent .

What I did was to allow the steamdrum to extend down past the tubes to act as a deflector, the steam drum diameter being quite large compared to the piping will have very low velocity thus (hopefully) preventing carry over.

-Ron

What I did was to allow the steamdrum to extend down past the tubes to act as a deflector, the steam drum diameter being quite large compared to the piping will have very low velocity thus (hopefully) preventing carry over.

-Ron

-

johnp

- Full Steam Ahead

- Posts: 242

- Joined: Mon Nov 23, 2009 6:43 pm

- Boat Name: Cardinal Queen

- Location: Richmond Hill, Ontario, Canada

Re: Olfeldt

my local tube bending/boiler supply company said they can make the coils but will have to weld the tail on one end.

What do you guys think?

What do you guys think?

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Olfeldt

"to weld the tail on one end"

I do not understand, could you please describe this?

I do not understand, could you please describe this?

-

johnp

- Full Steam Ahead

- Posts: 242

- Joined: Mon Nov 23, 2009 6:43 pm

- Boat Name: Cardinal Queen

- Location: Richmond Hill, Ontario, Canada

Re: Olfeldt

When you roll the coil you hol one end of the pipe and coil the pipe. You end up with a short straight piece that would enter the main drum and get welded. At the other end there will be no straight portion. ( see above pic/drawing).

-

Jack Innes

- Warming the Engine

- Posts: 84

- Joined: Mon Sep 30, 2013 9:12 pm

- Boat Name: Mazeppa

- Location: Brooklin, Ontario, Canada

Re: Olfeldt

I do not fully understand the process but could you not bend an extra coil & then heat & straighten the end without the needed straight section to create the "tail"?