Onboard Condenser sizing

-

JonRiley56

- Full Steam Ahead

- Posts: 340

- Joined: Sat Oct 08, 2011 12:58 am

Onboard Condenser sizing

All,

I have been away from the forum for a bit playing with a 1956 Willys, but now my thoughts are turning back to steam. My homebuilt onboard condenser malfunctioned on my last fall and I ended up getting seawater in my condensate return. It would seem that the 50ft SS coil I was running my steam through developed a hole of some sort.

I found prebuilt SS condensers that are reasonably priced. here is the link. http://www.brazetek.com/docs/pdf/st-specifications.pdf

How do I figure out what size I need ? I will be running a 3x4 simple at 100psi. My safety is set to go at 150psi, so that would be my max, but I prefer to run lower. I am running on the bay, so my feedwater is relatively cold, probably under 70F. My raw water pump will move up to 7gm. There is about a 24" head to the exit point in the hull (after the heat exchanger) and the connections on the exchanger body are larger than the pump in let and outlet so will not restrict. The only restriction will be in the shell of the exchanger itself if there is any.

Any help would be appreciated as always !

jon

I have been away from the forum for a bit playing with a 1956 Willys, but now my thoughts are turning back to steam. My homebuilt onboard condenser malfunctioned on my last fall and I ended up getting seawater in my condensate return. It would seem that the 50ft SS coil I was running my steam through developed a hole of some sort.

I found prebuilt SS condensers that are reasonably priced. here is the link. http://www.brazetek.com/docs/pdf/st-specifications.pdf

How do I figure out what size I need ? I will be running a 3x4 simple at 100psi. My safety is set to go at 150psi, so that would be my max, but I prefer to run lower. I am running on the bay, so my feedwater is relatively cold, probably under 70F. My raw water pump will move up to 7gm. There is about a 24" head to the exit point in the hull (after the heat exchanger) and the connections on the exchanger body are larger than the pump in let and outlet so will not restrict. The only restriction will be in the shell of the exchanger itself if there is any.

Any help would be appreciated as always !

jon

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Onboard Condenser sizing

There can be problems with stainless steel in stagnant sea water conditions, resulting in very rapid corrosion. I am no corrosion expert but I know some stainless steels corrode very rapidly in sea water that is not moving, while continuously keeping 3 feet per second velocity has no problems. The website that you reference has warnings about salt water, contact them about your application and salt conditions.

These stainless steel "pool heater" type heat exchangers are sized just right for launch condensers, are inexpensive on e-bay, and have the shell side connections just right to use as a condenser, with the shell inlet/outlet 180 degrees apart. This is ideal for steam in/condensate out arrangement. I plan to use one on the Margaret S., which runs almost exclusively on fresh water, but need to find one of those "round tuits" before I can install the condenser.

Heat exchangers with copper or brass tubes work well in sea water, and there are plenty of them on e-bay.

Are you planning to exhaust at atmospheric pressure and just recover condensate, or do you plan to run with vacuum exhaust? As you know the vacuum exhaust is more efficient, but requires a vacuum pump/wet air pump, and more surface area in the condenser tubes. Answer this and I will cook up a size for your application.

These stainless steel "pool heater" type heat exchangers are sized just right for launch condensers, are inexpensive on e-bay, and have the shell side connections just right to use as a condenser, with the shell inlet/outlet 180 degrees apart. This is ideal for steam in/condensate out arrangement. I plan to use one on the Margaret S., which runs almost exclusively on fresh water, but need to find one of those "round tuits" before I can install the condenser.

Heat exchangers with copper or brass tubes work well in sea water, and there are plenty of them on e-bay.

Are you planning to exhaust at atmospheric pressure and just recover condensate, or do you plan to run with vacuum exhaust? As you know the vacuum exhaust is more efficient, but requires a vacuum pump/wet air pump, and more surface area in the condenser tubes. Answer this and I will cook up a size for your application.

- Attachments

-

- PoolHeater.JPG (58.53 KiB) Viewed 14205 times

-

JonRiley56

- Full Steam Ahead

- Posts: 340

- Joined: Sat Oct 08, 2011 12:58 am

Re: Onboard Condenser sizing

Hi Fred,

Good to hear from you !! I am not planning on using a vacuum pump. I am just going to return at atmospheric pressure, using the exhaust steam pressure to return the condensate to the hotwell.

The way I am set up I have the pump and inlet for the sea water that runs through shell lower in the hull than the inlet to the shell of the heat exhanger. I do not have a check valve on the supply line to the exhanger itself. I have physical valves I can close, but not automatic back flow prevention.

When I pull the boat, the shell of the exchanger actually drains back through the pump and out the pick up opening, so the shell empties. In that case would it be OK for me to use a stainless unit ? When I am under way I have the pump running moving seawater through the exchanger at a pretty good clip.

thanks !

jon

Good to hear from you !! I am not planning on using a vacuum pump. I am just going to return at atmospheric pressure, using the exhaust steam pressure to return the condensate to the hotwell.

The way I am set up I have the pump and inlet for the sea water that runs through shell lower in the hull than the inlet to the shell of the heat exhanger. I do not have a check valve on the supply line to the exhanger itself. I have physical valves I can close, but not automatic back flow prevention.

When I pull the boat, the shell of the exchanger actually drains back through the pump and out the pick up opening, so the shell empties. In that case would it be OK for me to use a stainless unit ? When I am under way I have the pump running moving seawater through the exchanger at a pretty good clip.

thanks !

jon

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Onboard Condenser sizing

The conventional way to arrange a condenser is with the cooling water flow inside the tubes, steam outside the tubes. The British early standard steam surface condensers had the steam inside the tubes, and this can work, but they abandoned this arrangement sometime in the mid-19th century, virtually all condensers I have seen since then are with the cooling water inside the tubes.

When you get your boat home after an outing, flush out the sea water circuit of a stainless HX with good water. I do not know if anodes will help here, we certianly use them on large industrial condensers. Also consider the Copper or Brass HX tubes, then virtually no worry.

Anyone on the forum know about stainless problems with salt water?

When you get your boat home after an outing, flush out the sea water circuit of a stainless HX with good water. I do not know if anodes will help here, we certianly use them on large industrial condensers. Also consider the Copper or Brass HX tubes, then virtually no worry.

Anyone on the forum know about stainless problems with salt water?

-

JonRiley56

- Full Steam Ahead

- Posts: 340

- Joined: Sat Oct 08, 2011 12:58 am

Re: Onboard Condenser sizing

Hey Fred,

I can certainly run the water through the tubes, no problem. Any idea on what size I should be looking at ? 300,000 btu ??

jon

I can certainly run the water through the tubes, no problem. Any idea on what size I should be looking at ? 300,000 btu ??

jon

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

Re: Onboard Condenser sizing

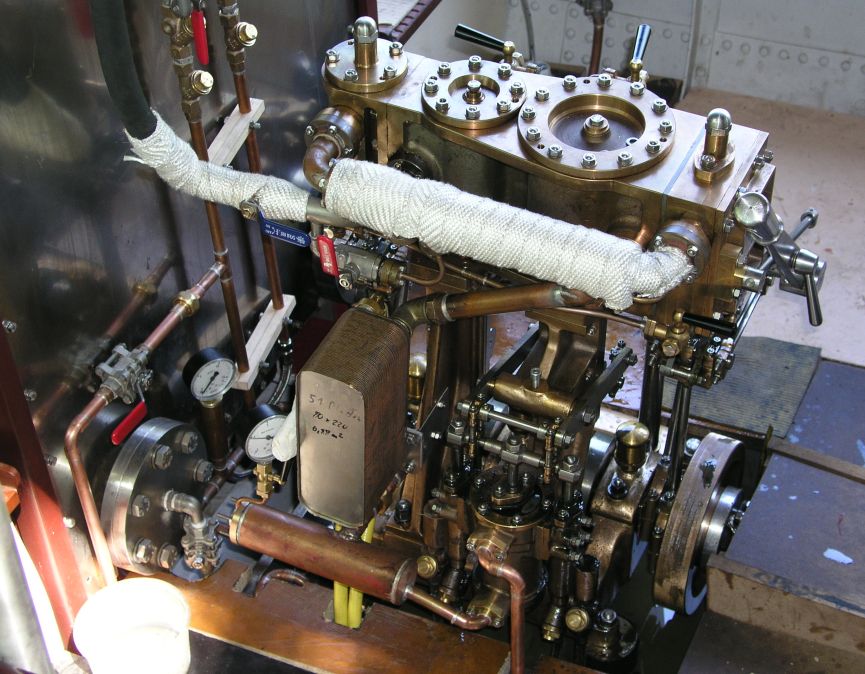

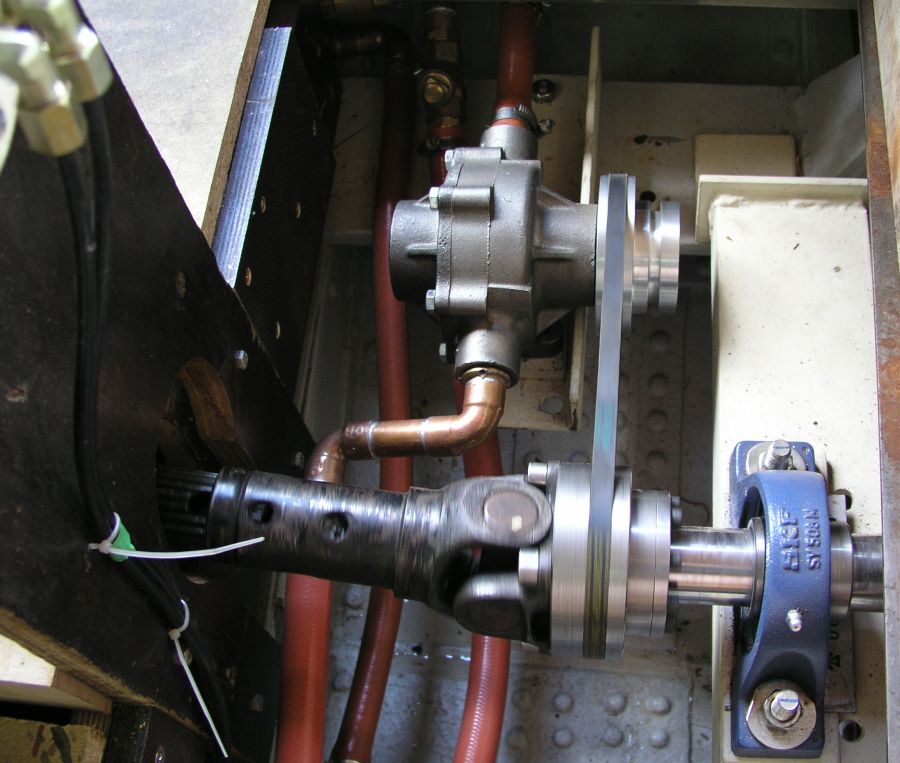

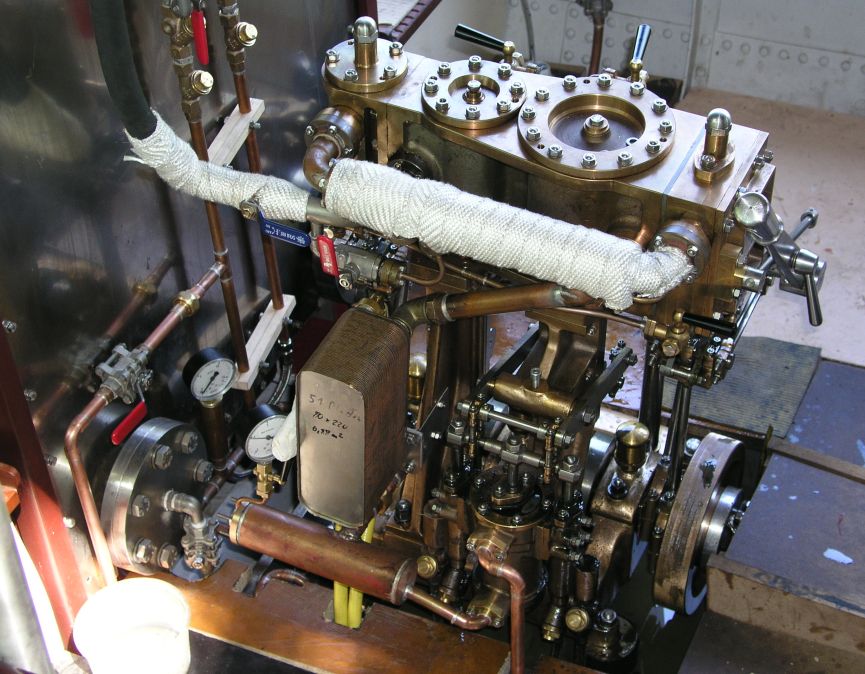

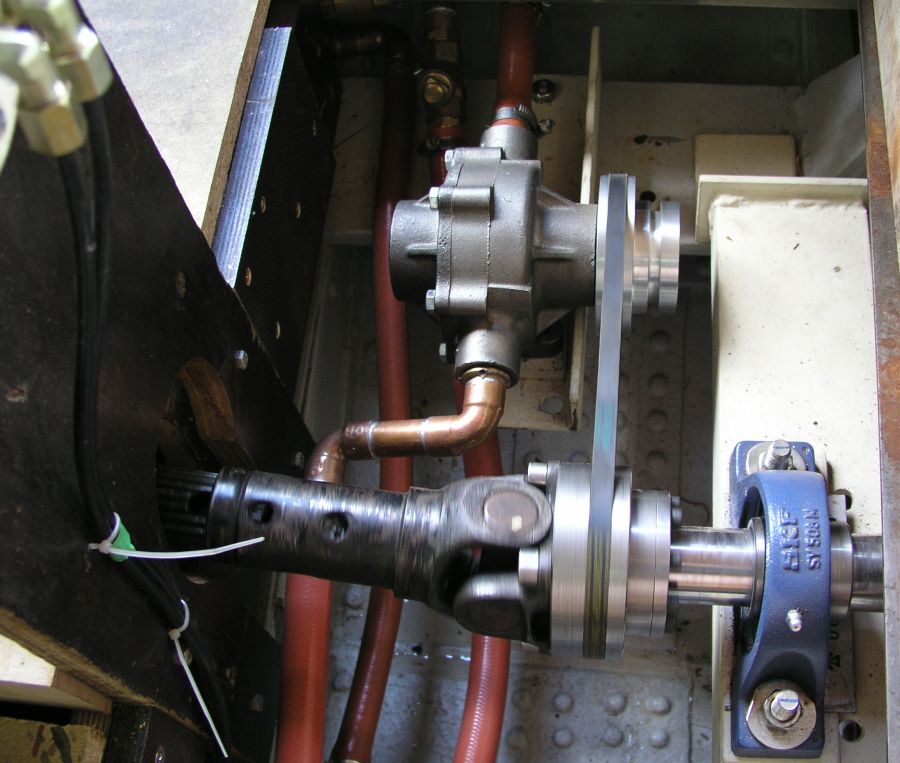

Have a look at my installation on Emma:

0.88 m² exchange surface on 51 stainless plates.

better than -0,9 bar vaccuum - best in town...

Belt driven Hypro roller pump (type 7560).

22 liter/minute at 250 rpm

intake water 18°C - outlet 45°C - condensate 50°C

0.88 m² exchange surface on 51 stainless plates.

better than -0,9 bar vaccuum - best in town...

Belt driven Hypro roller pump (type 7560).

22 liter/minute at 250 rpm

intake water 18°C - outlet 45°C - condensate 50°C

Rainer

www.steamboating.de

www.steamboating.de

-

JonRiley56

- Full Steam Ahead

- Posts: 340

- Joined: Sat Oct 08, 2011 12:58 am

Re: Onboard Condenser sizing

Hey Rainer,

Ich Liebe das.... Or something to that effect.

I always feel decidedly uneducated around you guys who speak multiple languages.

I have been of the mind that tube and shell exchangers are less problematic than plate types and easier to clean if necessary.

Does it make a difference that I am running on salt water? Is build up going to be an issue ? I know that in our production plants we get build up in our exchangers that can impede flow.

Your thoughts would be appreciated.

Jon

Ich Liebe das.... Or something to that effect.

I always feel decidedly uneducated around you guys who speak multiple languages.

I have been of the mind that tube and shell exchangers are less problematic than plate types and easier to clean if necessary.

Does it make a difference that I am running on salt water? Is build up going to be an issue ? I know that in our production plants we get build up in our exchangers that can impede flow.

Your thoughts would be appreciated.

Jon

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

Re: Onboard Condenser sizing

I don't know - if you run enough water through it, it will stay cool enough to prevent the salt from falling out and sticking to your exchange surface - my opinion.Jon wrote:Does it make a difference that I am running on salt water?

everybody is trying to tell you - I run Emma about 2-3000 km already and never had an issue with it. I didn't run her in salt water - but Emma was located in Berlin with "fertile water" with lots of alga in it and now in Hannover where the man build Mittellandkanal went right through a chalk hill so that you can lay your bricks with this water... Vacuum is still the same!Emma at the left chalk mine for cement production at the right (it's much deeper as the water line already)...Jon wrote:Is build up going to be an issue ?

Only issue are the filters at the water intake - you should keep them clean. Once in a lock a fright barge dispersed so much mud that I didn't got a vacuum and the engine jammed - you should have a bypass for such situations.

Don't worry - if this time comes - just exchange the exchanger.Jon wrote:I know that in our production plants we get build up in our exchangers that can impede flow.

Don't discuss your problems - feel it

Rainer

www.steamboating.de

www.steamboating.de

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Onboard Condenser sizing

From the BT website (brazetek.com):

"Stainless Steel Heat Exchangers: Not for use in:

● Salt water pools.

● Marine applications.

● Liquids containing hydrochloric acid, sulphuric acid and other chemicals known to corrode 316L stainless steel"

"Brazetek Shell & Tube heat exchangers are available in two series. ST series are 316L stainless steel shell and tube heat exchangers. STX series are titanium shell & tube heat exchangers. Both types are fully-welded and can be utilized in a variety of applications. Titanium heat exchangers are commonly used in marine applications such as salt water or others where corrosive liquids are present."

The Titanium heat exchangers cost about double the stainless price, but the Tiatnium will never have corrosion problems. I plan to buy the stainless model for the Margaret S., but I go into salt water only about 5 hours so far in three years. I will keep it well flushed after use if I need to go in salt water, and my reserve feed tank is not enough water to last for the trip in salt water. Your operation in salt almost always warrants the titanium option.

Condenser sizing is fairly easy, since the FAQ section of this forum addresses your application very nearly. The tech stuff that follows is for engineer nerds, but the answers are at the end, skip to the last sentences for that!.

From FAQ " Launch Engines - Output Power"

The 3 x 4 engine can produce about 5.5 horsepower

From FAQ "Launch Engines Steam Consumption"

A 5-1/2 horsepower steam plant would require 30 + 5.5 x 30 = 195 PPH, (pounds of steam per hour)

From FAQ "Boiler Output & Efficiency"

Heat to the boiler water is about 1000 BTU per pound produced, so your steam energy from the boiler = 195 PPH x 1000 BTU per pound of steam

= 195,000 BTU boiler output.

The steam engine converts some of this energy into useful work, and one horsepower is 2545 BTU per hour, so the engine is producing an output of

5.5 x 2545 = 14,000 BTU per hour,

The energy balance tells us 195,000 BTU per hour into the steam, 14,000 BTU per hour is converted to work, so 195,000 - 14,000 = 181,000 BTU per hour to be removed in the condenser. 181,000 BTU per hour is your design basis heat load.

The heat exchangers we are talking about are sized (vendor data) based on water to water duty, and in steam condensing they will have similar performance, (a little better with clean steam, perhaps a little worse with oil laden engine exhaust steam). The BTU ratings for those heat exchangers are based on 140F temperature differential.

For your steamboat duty we have say 70F cooling water 7 GPM.

The temperature rise in the cooling water is 7 GPM * 500 PPH/GPM = 3500 PPH

181,000 BTU / 3500 PPH Water with specific heat of one BTU/pound-F = 50F temperature rise.

So the cooling water goes in at 70F, comes out at 70 + 50 = 120F, and the average cooling water temperature is about 95F.

Condensing at 212F, the nominal temperature difference is 212 - 95 = 117F, only about 85% of what the vendor data is based on, so you need a heat exchanger rating that is about 120% of your design basis heat load.

181,000 x 1.20 = 216,000 BTU per hour heat exchanger rating is required.

The vendor data lists heat exchangers rated at 210,000 BTU/hr and 300,000 BTU/hr. If you select the 210,000 BTU/hr size, you will be able to condense almost all your exhaust steam at full power, back off a few percent on power and all of the steam will condense as long as the heat exchanger is not fouled with engine oil, etc. Selecting the 300,000 BTU rated heat exchanger gives a generous margin in sizing, which would allow much more fouling while still maintaining full condensing capability. The 300,000 BTU/hr rated heat exchanger would also be sized to allow a vacuum condensing operation in the future if you are ever wanting to make that setup.

So Jon, you had the sizing right already, 300,000 BTU rating, no need to ask!

"Stainless Steel Heat Exchangers: Not for use in:

● Salt water pools.

● Marine applications.

● Liquids containing hydrochloric acid, sulphuric acid and other chemicals known to corrode 316L stainless steel"

"Brazetek Shell & Tube heat exchangers are available in two series. ST series are 316L stainless steel shell and tube heat exchangers. STX series are titanium shell & tube heat exchangers. Both types are fully-welded and can be utilized in a variety of applications. Titanium heat exchangers are commonly used in marine applications such as salt water or others where corrosive liquids are present."

The Titanium heat exchangers cost about double the stainless price, but the Tiatnium will never have corrosion problems. I plan to buy the stainless model for the Margaret S., but I go into salt water only about 5 hours so far in three years. I will keep it well flushed after use if I need to go in salt water, and my reserve feed tank is not enough water to last for the trip in salt water. Your operation in salt almost always warrants the titanium option.

Condenser sizing is fairly easy, since the FAQ section of this forum addresses your application very nearly. The tech stuff that follows is for engineer nerds, but the answers are at the end, skip to the last sentences for that!.

From FAQ " Launch Engines - Output Power"

The 3 x 4 engine can produce about 5.5 horsepower

From FAQ "Launch Engines Steam Consumption"

A 5-1/2 horsepower steam plant would require 30 + 5.5 x 30 = 195 PPH, (pounds of steam per hour)

From FAQ "Boiler Output & Efficiency"

Heat to the boiler water is about 1000 BTU per pound produced, so your steam energy from the boiler = 195 PPH x 1000 BTU per pound of steam

= 195,000 BTU boiler output.

The steam engine converts some of this energy into useful work, and one horsepower is 2545 BTU per hour, so the engine is producing an output of

5.5 x 2545 = 14,000 BTU per hour,

The energy balance tells us 195,000 BTU per hour into the steam, 14,000 BTU per hour is converted to work, so 195,000 - 14,000 = 181,000 BTU per hour to be removed in the condenser. 181,000 BTU per hour is your design basis heat load.

The heat exchangers we are talking about are sized (vendor data) based on water to water duty, and in steam condensing they will have similar performance, (a little better with clean steam, perhaps a little worse with oil laden engine exhaust steam). The BTU ratings for those heat exchangers are based on 140F temperature differential.

For your steamboat duty we have say 70F cooling water 7 GPM.

The temperature rise in the cooling water is 7 GPM * 500 PPH/GPM = 3500 PPH

181,000 BTU / 3500 PPH Water with specific heat of one BTU/pound-F = 50F temperature rise.

So the cooling water goes in at 70F, comes out at 70 + 50 = 120F, and the average cooling water temperature is about 95F.

Condensing at 212F, the nominal temperature difference is 212 - 95 = 117F, only about 85% of what the vendor data is based on, so you need a heat exchanger rating that is about 120% of your design basis heat load.

181,000 x 1.20 = 216,000 BTU per hour heat exchanger rating is required.

The vendor data lists heat exchangers rated at 210,000 BTU/hr and 300,000 BTU/hr. If you select the 210,000 BTU/hr size, you will be able to condense almost all your exhaust steam at full power, back off a few percent on power and all of the steam will condense as long as the heat exchanger is not fouled with engine oil, etc. Selecting the 300,000 BTU rated heat exchanger gives a generous margin in sizing, which would allow much more fouling while still maintaining full condensing capability. The 300,000 BTU/hr rated heat exchanger would also be sized to allow a vacuum condensing operation in the future if you are ever wanting to make that setup.

So Jon, you had the sizing right already, 300,000 BTU rating, no need to ask!

-

Albert

- Steam on Deck

- Posts: 46

- Joined: Sat Sep 22, 2012 12:32 pm

- Boat Name: Min Deern

- Location: Kiel - Germany

Re: Onboard Condenser sizing

My boat "Min Deern" features a similar condensing system as the one on Rainer's "Emma". I run the boat on the Atlantic coast (Douarnenez in France) and - several years now - in brackish water (river Eider in Northern Germany). Last inspection showed no signs of corrosion whatsoever. No performance detriment of the reheating/condensing systems after some 8 years of operation.

Should the stainless steel plate heat exchanger (condenser) become corroded sometime in the future... no worry, an exchange costs no more than $ 60.00 (eBay).

Albert

Should the stainless steel plate heat exchanger (condenser) become corroded sometime in the future... no worry, an exchange costs no more than $ 60.00 (eBay).

Albert