Regarding the Balanced slide valve on the Leek, I am not convinced that the balance would be very useful as per the drawing? I would certainly machine “water grooves” in the face running on the valve chest cover to seal this. The exhaust appears to exit through the cover, this is not always desirable and balanced valves do not need this if its better to exit in the conventional way.

As I understand it the theoretical balance would be calculated as follows. On the valve working side:- the area of the valve x steam pressure less the area of the balance seal x steam pressure, However additional loading is imposed by the balance valve :- the area of the balance disc x steam pressure less the area of the seal x steam pressure.

With a large balance disc needed to allow exhausting through the cover this must be significant.

With an unbalanced valve the exhaust cavity pressure is trying to lift the valve, I have ignored this effect on a balanced valve.

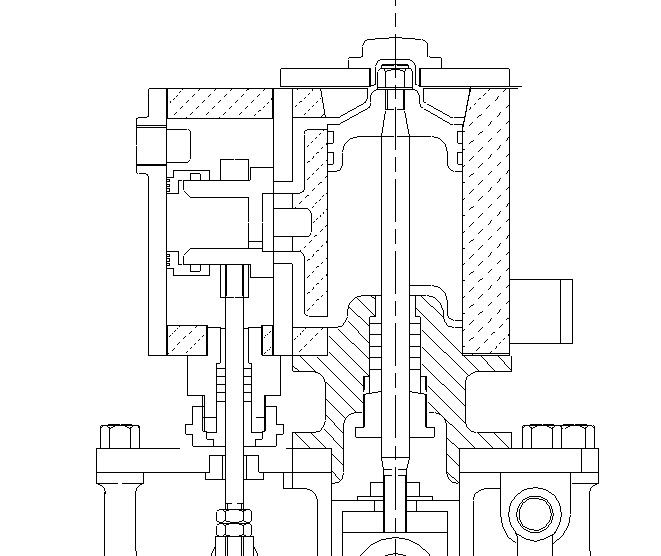

On my own design, the balance disc is smaller as the centre space is communicated to the exhaust cavity by a drilling only, this has the added advantage that should a failure of the balance system occur, the hole can be blocked and the valve run as a conventional type. Below is my design giving about 60% loading based on the above.