I have had to repair my Semple boiler and I had one of my employees who is an excellent welder replace the tubes. ( i know, TABOO for not spending the money for a certified welder but) I want to fill the boiler with water and then pump it up to XXX? pressure to make a static test. How would YOU pump up the hydraulic pressure? and how high? I don't want to test the failure pressure. I have a make up hand pump on the boat and I could see how strong i am. I have hydraulic oil cylinders and pumps but i think i would only want water in the system. Any suggestions?

Thanks

pressure testing a newly repaired boiler

-

wsmcycle

- Full Steam Ahead

- Posts: 218

- Joined: Sun Mar 13, 2011 5:43 pm

- Boat Name: FEARLESS,l'il steamy

- Location: Fort Smith Arkansas USA

pressure testing a newly repaired boiler

LIGHT THE FIRE!!

Re: pressure testing a newly repaired boiler

Must-reading: http://www.northweststeamsociety.org/Pa ... safety.htm and http://www.northweststeamsociety.org/Pa ... -FINAL.pdf

These provide a good overview (but not a comprehensive everything-you-ever-needed-to-know treatment) of safety procedures and standards generally and do-it-yourself boiler testing. From the good folks at Northwest Steam Society.

These provide a good overview (but not a comprehensive everything-you-ever-needed-to-know treatment) of safety procedures and standards generally and do-it-yourself boiler testing. From the good folks at Northwest Steam Society.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: pressure testing a newly repaired boiler

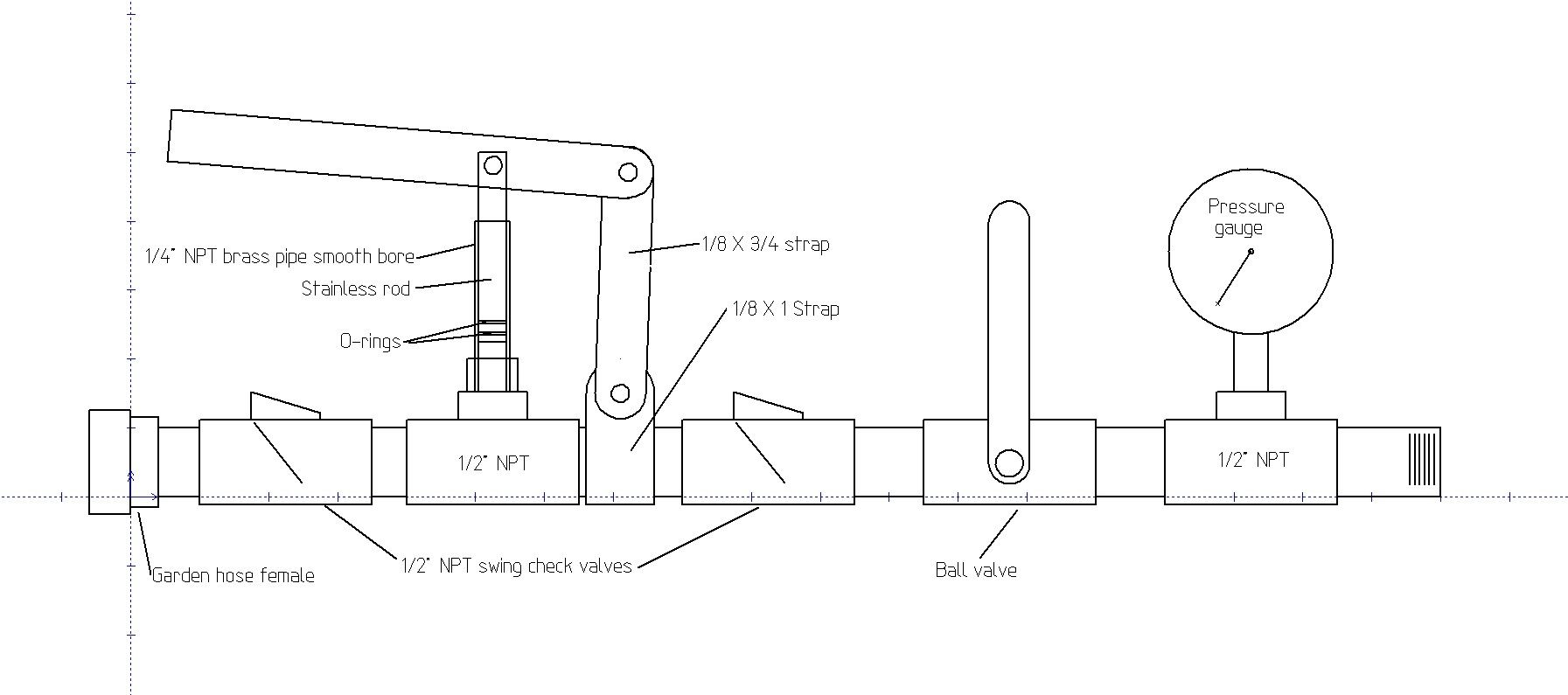

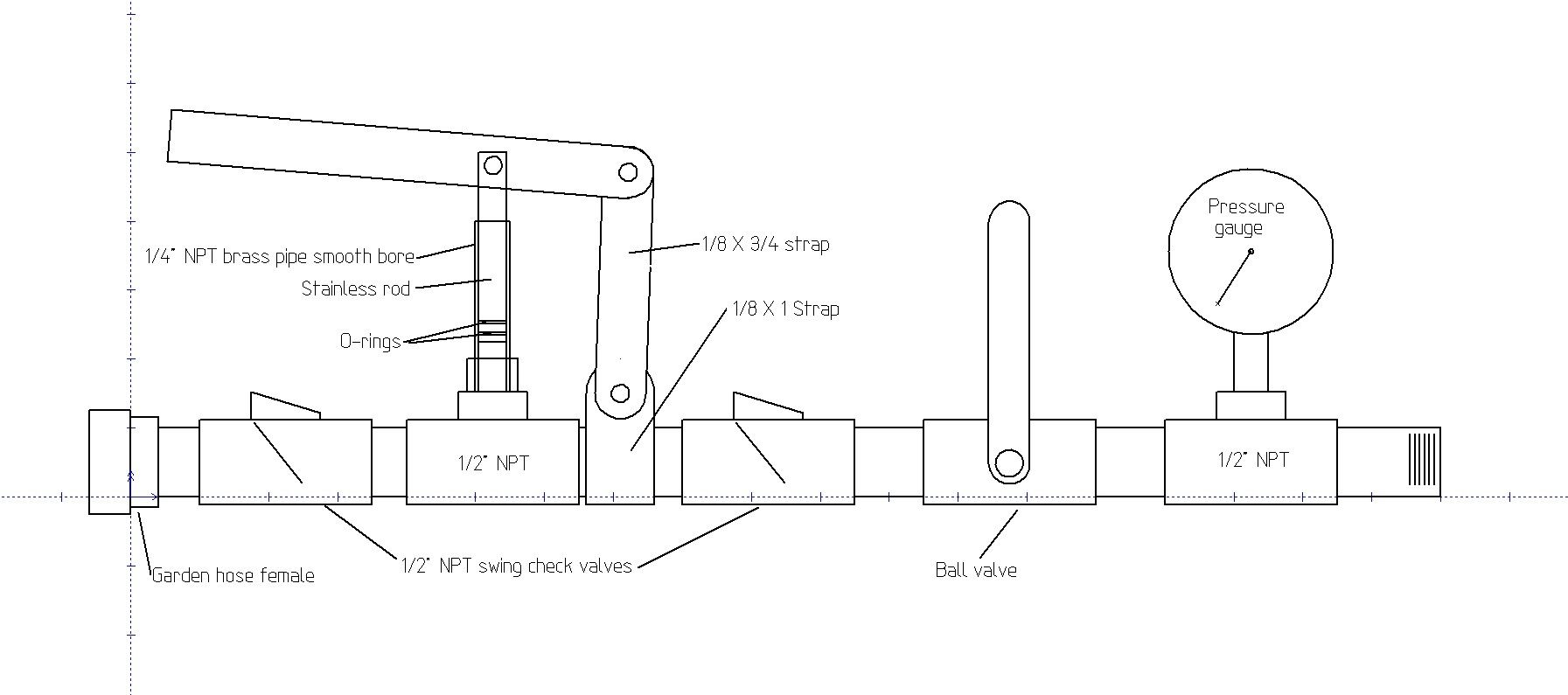

Hydrostatic testing is pretty easy to do and even making a pump for it is easy as well. The pump can be as simple as a piece of 1/4" smooth bore brass pipe with a plunger and O-rings fitted. Water will not compress so even a very small pump can test a very large boiler. If you have a small hydraulic hand pump, that will work just fine. Remove the safety valve, pay attention that all of your gauges can handle the intended test pressure of 1-1/2 times the relief valve pressure. I usually go two times higher as I'm safetied for 100psi. Make sure the boiler is completely full. On the tug there isn't a fitting up high to get all of the air out, so use a piece of curved plastic tube up on the top sheet to vent all of the air out. As long as there is no air, it's not dangerous at all. If the test gauge isn't jumping about 30 pounds per stroke of the pump, there is air still in the boiler somewhere.

Here is a simple pump to make that I just drew up. Only machining is the plunger and O-ring grooves. We made one of these a few years ago, it works perfectly.

-Ron

Here is a simple pump to make that I just drew up. Only machining is the plunger and O-ring grooves. We made one of these a few years ago, it works perfectly.

-Ron

-

steamdon-jr

- Full Steam Ahead

- Posts: 143

- Joined: Thu Apr 05, 2012 10:54 pm

- Boat Name: SL Phoebe Snow

- Location: Quakertown, PA

- Contact:

Re: pressure testing a newly repaired boiler

As Ron said, you want absolutely no air in the boiler as when you pump he boiler full air will compress but water will not, you should have no safety valve on the boiler but a pressure gauge on the boiler and pump are good, I pump it to 1 1/2 times my safety valve pressure once up to pressure I close the valve leading into the boiler and let it sit to look for weeps, if your appliances are on then they are closed as well minus the pressure gauge. I like to have the water around 110 degrees.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: pressure testing a newly repaired boiler

One thing should be noted: Monitor the test closely. Pay attention to the test pressure, especially if the test is being conducted outside. The heat from the sun or anything that will warm the water during the test will cause the water to expand and raise the pressure significantly.

-Ron

-Ron

- Lopez Mike

- Full Steam Ahead

- Posts: 1925

- Joined: Wed Dec 07, 2011 6:41 am

- Boat Name: S.L. Spiffy

- Location: Lopez Island, Washington State, USA

Re: pressure testing a newly repaired boiler

I guess I don't get why the hand feed water pump wouldn't do fine for hydro testing.

And if you don't have a hand feed water pump you probably shouldn't fire up the boiler anyway.

Or am I missing something? Are there boats without a hand pump?

And if you don't have a hand feed water pump you probably shouldn't fire up the boiler anyway.

Or am I missing something? Are there boats without a hand pump?

If you think you are too small to make a difference, try sleeping with a mosquito.

Dalai Lama

Dalai Lama

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: pressure testing a newly repaired boiler

Depending on how it is plumbed, using the boats hand feed pump is not very convenient. Non-condensing systems pull through the hull, getting water to the hand pump would be difficult without undoing piping etc. The piston of a properly sized emergency hand feedpump is difficult to use at test pressures. i.e. 1 sq/in of piston face area results in a piston force of one pound per pound of head pressure. 250 pounds could be very difficult to achieve. It's the same reason hydraulic jacks etc have very small pistons.

The pump I posted above allows using a garden hose to fill the boiler through 1/2" pipe and then the pump is very easy to use for testing. Convenient ball valve for isolating the pump from the test - all those features..

-Ron

The pump I posted above allows using a garden hose to fill the boiler through 1/2" pipe and then the pump is very easy to use for testing. Convenient ball valve for isolating the pump from the test - all those features..

-Ron

- Dhutch

- Full Steam Ahead

- Posts: 184

- Joined: Wed Jan 26, 2011 12:03 am

- Boat Name: SNB Emily Anne

- Location: Staffordshire (UK)

- Contact:

Re: pressure testing a newly repaired boiler

I do not know the size or working pressure of this boiler, but overall I really do not feel overly happy commenting on this thread at all.

However, assuming the boiler is of an appropriate design and was certified when new you should have documentation for it which will state the pressure it was tested to originally, which will given an upper limit. Boiler inspectors and inspection schemes will then have their own guidelines for the pressure and frequency of routine hydraulic tests.

In the case of our boiler which is a vertical fire tube boiler, with welded steel and steel tubes, the designed working pressure is 200psi, the original test pressure was twice the working pressure at 400psi. Our boiler inspectors perform the routine hydraulic test to 1.5 times WP and hence at 300psi when inspecting for leaks etc. The frequency for this is 4-5years, somewhat at the inspectors discretion. It was also tested to this pressure when re-tubed (expanded only, stay tubes where not changed).

Obviously however I am not qualified to advise on boilers and I really can only suggest you consult the original design specification and test paperwork, and or someone who is a qualified boiler inspector.

Holding pressure for a single cold hyd test, is a very long way from ensuring the welded are suitable. While not qualified with respect to boilers, I am an qualified mechanical engineer with experience in welded structures, and without knowing the grade of steel, quality of weld, you cannot predict component life even of a known design and application. Any manor of minor deviations in process can reduce the life 100 times over.

Daniel

However, assuming the boiler is of an appropriate design and was certified when new you should have documentation for it which will state the pressure it was tested to originally, which will given an upper limit. Boiler inspectors and inspection schemes will then have their own guidelines for the pressure and frequency of routine hydraulic tests.

In the case of our boiler which is a vertical fire tube boiler, with welded steel and steel tubes, the designed working pressure is 200psi, the original test pressure was twice the working pressure at 400psi. Our boiler inspectors perform the routine hydraulic test to 1.5 times WP and hence at 300psi when inspecting for leaks etc. The frequency for this is 4-5years, somewhat at the inspectors discretion. It was also tested to this pressure when re-tubed (expanded only, stay tubes where not changed).

Obviously however I am not qualified to advise on boilers and I really can only suggest you consult the original design specification and test paperwork, and or someone who is a qualified boiler inspector.

Holding pressure for a single cold hyd test, is a very long way from ensuring the welded are suitable. While not qualified with respect to boilers, I am an qualified mechanical engineer with experience in welded structures, and without knowing the grade of steel, quality of weld, you cannot predict component life even of a known design and application. Any manor of minor deviations in process can reduce the life 100 times over.

Daniel