Page 1 of 2

Stuart no 6

Posted: Wed Sep 02, 2020 6:22 am

by ALLAN

Hi, I am rebuilding a Stuart no 6 engine and am wondering if anyone has drawings for the no 6. I have purchased a copy of the 6A drawings from Stuart Turner but they are significantly different to the no 6.

Regards

Allan familton

Re: Stuart no 6

Posted: Wed Sep 02, 2020 7:03 am

by dampfspieler

Hi Allan,

you can find a No 6-drawing in "STEAMBOATS and modern steam launches", capture July - August 1961, page 18 and 19.

I generally recommend the book.

Best Dietrich

Re: Stuart no 6

Posted: Wed Sep 02, 2020 7:40 am

by ALLAN

Thank you Dietrich

Re: Stuart no 6

Posted: Thu Sep 03, 2020 9:57 pm

by Lopez Mike

Give some consideration to fitting a larger diameter H.P. valve rod. There has been more than one failure.

Re: Stuart no 6

Posted: Fri Sep 04, 2020 10:31 am

by ALLAN

Hi Mike,

The engine was built in the late 1950s early 60 and has run in Gypsy for over 30 years. it has 1/2 valve spindles in both valve chests so i am putting new 1/2 spindles in. it does have a different valve guide to the drawings.

It has a cross plate with bush mounted on 2 studs either side of the spindle so ill see how it goes. do you know where they fail?

Re: Stuart no 6

Posted: Fri Sep 04, 2020 2:42 pm

by Oilking

Allan,

The drawing in Steamboats and Modern Steam Launches shows the No.6 with 3/8" valve rods. Looks like your's has had the cure applied. Have fun with the project.

Dave

Re: Stuart no 6

Posted: Sat Sep 05, 2020 12:50 am

by Lopez Mike

The one I most recently dealt with had a broken 5/16" H.P. valve rod. To think, I thought I was making a big upgrade by going to 3/8"!

Re: Stuart no 6

Posted: Sat Sep 05, 2020 7:02 am

by dampfspieler

Hello Mike,

... had a broken 5/16" H.P. valve rod.

where was it broken. Only if this is known can it be changed successfully.

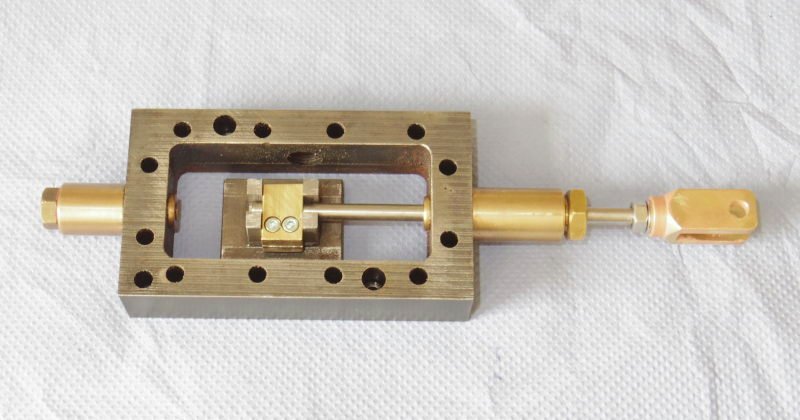

Here my solution of a valve rod.

--

Dietrich

Re: Stuart no 6

Posted: Sun Sep 06, 2020 6:21 pm

by fredrosse

dampfspieler, you have an excellent method of clamping the valve travel block to the valve rod, with infinite precision available for fine adjustment. I will follow that method on one of my future builds.

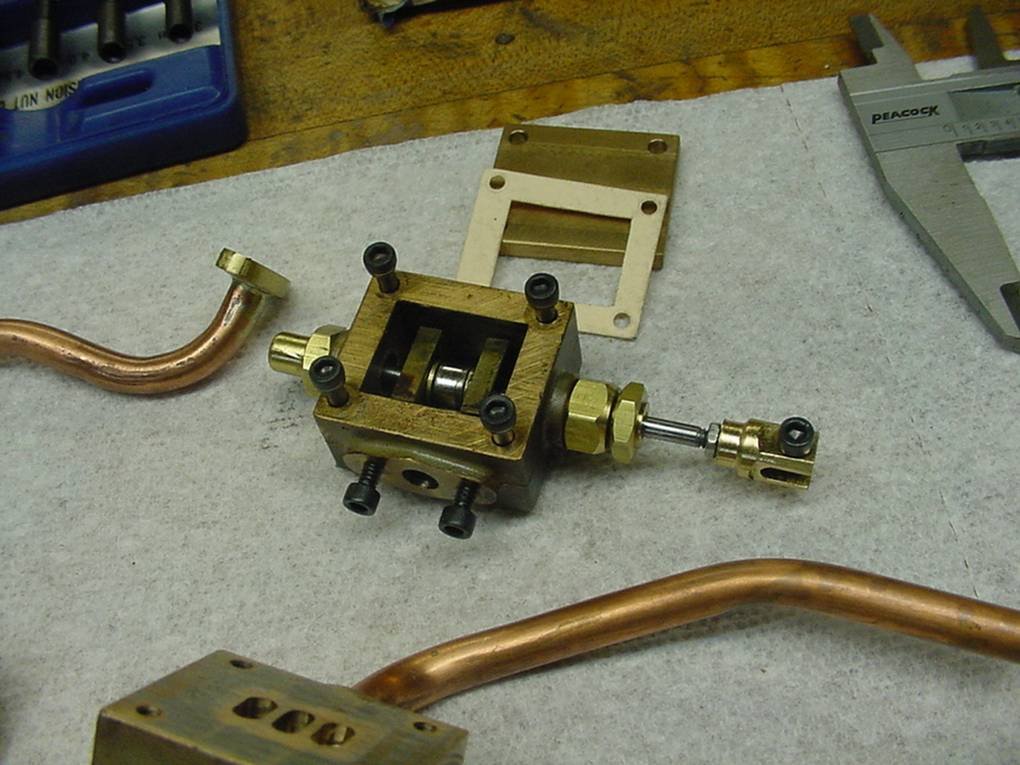

For small engines, I have made the valve rod longer, allowing bearing support at both ends of the steam chest. That can give good guided travel, without an outside slipper guide. Make the valve rod somewhat larger to complete that arrangement.

- SteamChest.jpg (136.99 KiB) Viewed 8448 times

Re: Stuart no 6

Posted: Tue Sep 08, 2020 3:15 am

by Lopez Mike

The one I fixed and the one I was told about both broke right where the threads started. Smaller effective diameter and some sharp edges resulting in stress risers.

I like your extended rod not that it would help the breakage at the threads so much but that it should reduce friction due to poor rod alignment.

Your clamping design makes for a good solution to the thread wearing where it goes through the valve block. You must, of course, still allow some play so that the valve can slide on the port face freely.

I prefer my piston valve with inside admission so that the valve rod packing gland is only exposed to the throttled steam. Much easier on the eccentric as well.