Page 7 of 7

Re: Sea Lion Engine build

Posted: Fri Apr 28, 2017 3:54 pm

by Lopez Mike

I did a little looking and I don't see the double taper thing. The ones I have found use a split bushing that fits a shaft on the I.D. (cylindrical) and is tapered on the O.D.

I had thoughts of buying the bushing and taper boring my old flywheel if there is enough material. Then tap a couple of holes in my flywheel (again, if there is enough meat) and install.

Any links?

Mike

Re: Sea Lion Engine build

Posted: Fri Apr 28, 2017 3:57 pm

by Lopez Mike

Oops! I just spotted the link at the end of Dietrick's post. Now to find that 25.4 mm one here in the technical backwater of the U.S.

Re: Sea Lion Engine build

Posted: Fri Apr 28, 2017 4:41 pm

by DetroiTug

Neat gadget, but a .050 cent key and well machined keyway works as well. Just remember to use Anti-seize compound on anything steel to steel on a boat, even those double taper split bushings. A taper is no guarantee it will disassemble easily. If it's rusted and locked, it isn't going to come apart without some heating and beating.

-Ron

Re: Sea Lion Engine build

Posted: Fri Apr 28, 2017 5:16 pm

by Lopez Mike

I dunno Ron. I've seen some taper lock couplings on my uncles' portable lumber mill that were buried in corrosion and filth. Two turns of the breaker screws and off they came.

I think it's just that I am offended by keyways. Just a really weak spline that causes damage when it fails.

I raced hydroplanes and we gave up on keys for the prop and the rudder shaft bell crank years ago. They just don't seem to stay together under extreme service.

I know. Keyways have a long service record and they will be around when I'm gone but the newer things I have on my engine now are great. Ball bearing mains and eccentrics. I just don't think about them any more.

I'll probably stay with my brass big end and plain bearing cross head just to have a couple of oilers to fuss with.

Re: Sea Lion Engine build

Posted: Fri Apr 28, 2017 6:17 pm

by DetroiTug

Yep, I have ball bearing mains and big ends on my twin and they are very easy to get along with. The eccentrics are steel and the straps are bronze and they've held up quite well also, just a shot of grease in the morning. The Locomobile engine originally had steel eccentrics and steel straps, I put bronze eccentrics on it, no trouble at all with them.

Keyways can be a pain, if they don't fit close or in an application where the load is reversed frequently, any side play turns bad in short order. A lot of that has to do with the material used as well. We typically use everything as drawn with no heat treat, and for keyways, that just doesn't hold up very well. Easy to deform the keyway under high loads, double edged sword though, harder material has higher probability of fracture. Pay your money, take your chances

-Ron

Re: Sea Lion Engine build

Posted: Sat Apr 29, 2017 2:13 am

by dampfspieler

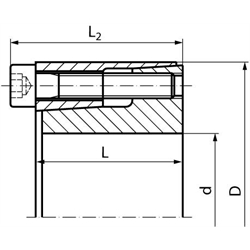

Here some pictures of my solution, i think they are self explanatory and can answer some questions. There are a lot of locking assemblies so anyboby can find a optimally one.

The old flywheel was fixed only with two setscrews and no keyways.

- construction principle of locking assemblies BAR

- BARV3.gif.jpeg (32 KiB) Viewed 11278 times

(linked from

https://www.maedler.de)

Dietrich

Re: Sea Lion Engine build

Posted: Sat Apr 29, 2017 6:15 pm

by Mike Rometer

Tap the link on Deitrich's post and the sectioned drawing shows it.

Re: Sea Lion Engine build

Posted: Fri Jun 02, 2017 4:38 am

by barts

Yes, Dampfspieler, that's exactly what I have in mind. Now to just find more time in the shop.

- Bart

Re: Sea Lion Engine build

Posted: Fri Jun 02, 2017 7:27 am

by cyberbadger

Lopez Mike wrote:I had thoughts of buying the bushing and taper boring my old flywheel if there is enough material. Then tap a couple of holes in my flywheel (again, if there is enough meat) and install.

Any links?

Mike

"As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley."

https://www.mcmaster.com/#split-taper-bushings/=17w1x3q

I'm sure martin sprockets makes what you want if this isn't it...

http://www.martinsprocket.com/

-CB

Re: Sea Lion Engine build

Posted: Fri Jun 02, 2017 3:28 pm

by Lopez Mike

I was going to go that way until I saw the bushing sets that Dampfspieler showed in his picture. Using his design means just a cylindrical bore in my flywheel. Much easier.