Page 6 of 16

Re: And Now for the Twin

Posted: Sun May 20, 2018 3:13 pm

by Mike Rometer

Not that I've actually done any more, except I have now acquired a copy of the drawings (I don't intend to follow them at all closely).

They show 5 fixings per head with one on the centre-line. That very neatly steps the outer four well away from the port area. As I said above "Too late" they are already drilled. Hmm, must get round to tapping them!

Re: And Now for the Twin

Posted: Sat Jul 28, 2018 8:11 pm

by Mike Rometer

Progress is slow and sporadic, but : -

The ali pistons are finished and fitted to the rods, which aren't yet cut to length. I've gone with two rings in one groove to maintain the 3.25" stroke that I wanted.

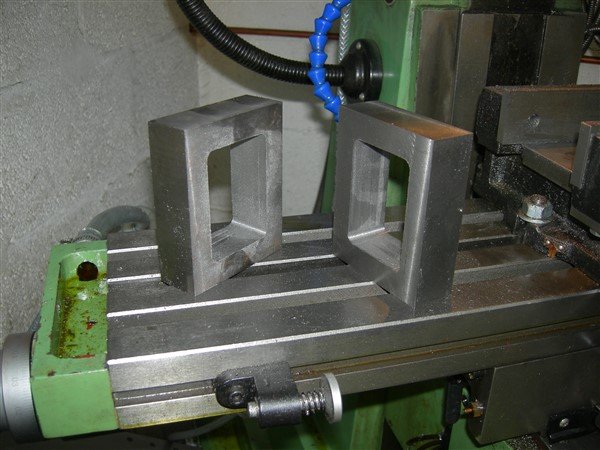

I acquired a large chunk of cast iron from which I've fashioned the valve chest blanks. Lot of metal still to remove from the middles.

- Steam Chests (7) (600 x 450).jpg (70.61 KiB) Viewed 24337 times

The crankshaft webs have been reduced to an overall thickness 0.750" with main bosses left at 1" for stiffness. I then made a fixture for the mill bed and bored the crankpin holes. They may just need a smidgeon more removing (reamer) before the pins are pressed in, after the shape of the weights has been machined.

- Crankshaft (12) (600 x 450).jpg (62.57 KiB) Viewed 24337 times

Lots of metal to come off yet!

Re: And Now for the Twin

Posted: Tue Jan 01, 2019 4:44 pm

by Mike Rometer

HNY Y' All.

I've just reviewed this thread and found several pictures that had got corrupted. I've tried to put them right but there is one left that refuses point blank to show itself in 'Edit', to allow its replacement. I tried (I might give it one more go)!

It has been a good 'Twin' day, not the first lately, but the other day's results were a bit boring and are yet to be finished. Namely the base plate and cylinder under plate. So far, trued up for accurate sizing and facing.

Progress has been with the valve/steam chests. Some cast iron was obtained some time ago, and I've spent a while ploughing out the centres. This method is cheaper and easier than making a pattern and then a 120mile round trip (twice) to a foundry.

- Steam Chests (8) (600 x 450).jpg (68.59 KiB) Viewed 24100 times

- Steam Chests (10) (600 x 450).jpg (52.21 KiB) Viewed 24100 times

- Steam Chests (11) (600 x 450).jpg (62.57 KiB) Viewed 24100 times

Tomorrow, if I get left alone by the Domestic Officer, I might get some fixing holes planned and drilled. Two on each side (8 total).

Re: And Now for the Twin

Posted: Sat Jan 12, 2019 5:48 pm

by Mike Rometer

- Main Bearings (2) (600 x 450).jpg (62.19 KiB) Viewed 24059 times

The base-plate marked out, drilled and tapped with the main bearings bolted down (upside down!). Further marking out has been done and the next stage is - remove the shaft and plough out the holes for the crank-webs etc. making sure to leave somewhere to bolt down the end pillars!

Re: And Now for the Twin

Posted: Sat Jan 12, 2019 8:41 pm

by DetroiTug

Mike,

It looks like you're doing a first class "best-o-gear" job on it.

Those pillow blocks in that service will outlast all of us. Give em a shot of white lithium grease occasionally. Curious though, not seeing a tail shaft to put a fly wheel on etc, not that a simple twin really needs one though.

-Ron

Re: And Now for the Twin

Posted: Sat Jan 12, 2019 10:31 pm

by Mike Rometer

That's only a length of drill rod for lining up the bearings. I still need to assemble the crankshaft, but the bits are made.

Re: And Now for the Twin

Posted: Tue Jan 15, 2019 8:49 pm

by Mike Rometer

After a short interlude Base-Plate work has continued.

- Base-Plate (3) (600 x 450).jpg (70.88 KiB) Viewed 24012 times

Truing to the machine was simple, just aligned it against the column, because the plate had been squared beforehand.

- Base-Plate (7) (600 x 450).jpg (77.21 KiB) Viewed 24012 times

Almost ready for the mounting angles to be welded on.

Re: And Now for the Twin

Posted: Thu Jan 17, 2019 3:23 am

by Steam Captain

Your project is very inspiring. Seeing all those pictures drive me even more to finish my lathe. Can I ask you how much power you designed the engine for? And what gear you will use?

I like the sturdy look of the pieces. It already looks like a powerhouse.

Re: And Now for the Twin

Posted: Thu Jan 17, 2019 9:40 am

by Mike Rometer

Ramon, the output of any steam engine is a product of how much you put in, i.e. the pressure from the boiler. At just 100 P.S.I.G. it should give a bit over 5Hp if that is pushed to 150 P.S.I.G. is will just about top 8HP. Somewhere in between would seem more likely, if I ever get it into a hull. I'm expecting to use Stephenson's link valve gear, but as I'm designing myself (more or less as I go along) that could change, but unlikely.

Re: And Now for the Twin

Posted: Thu Jan 17, 2019 11:26 am

by RGSP

Mike,

will you re-machine your engine bed plate after welding bits to it? The whole thing is probably small enough to put into an annealing oven if you can find one, or a potter's kiln would do at a pinch. Domestic ovens don't really get hot enough. I suppose that's why many engines have cast iron beds, although I quite like the idea of built-up beds designed carefully and bolted together.

Dick