Page 28 of 39

Re: DetroiTug's Tug is going together

Posted: Mon May 21, 2012 10:40 pm

by DetroiTug

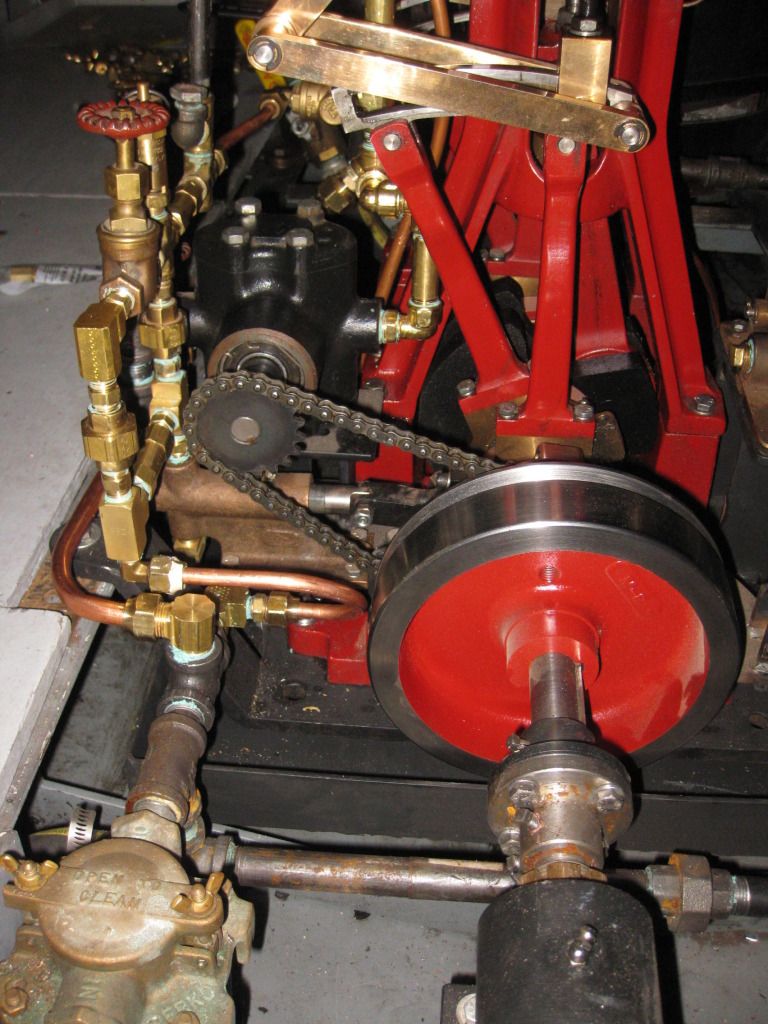

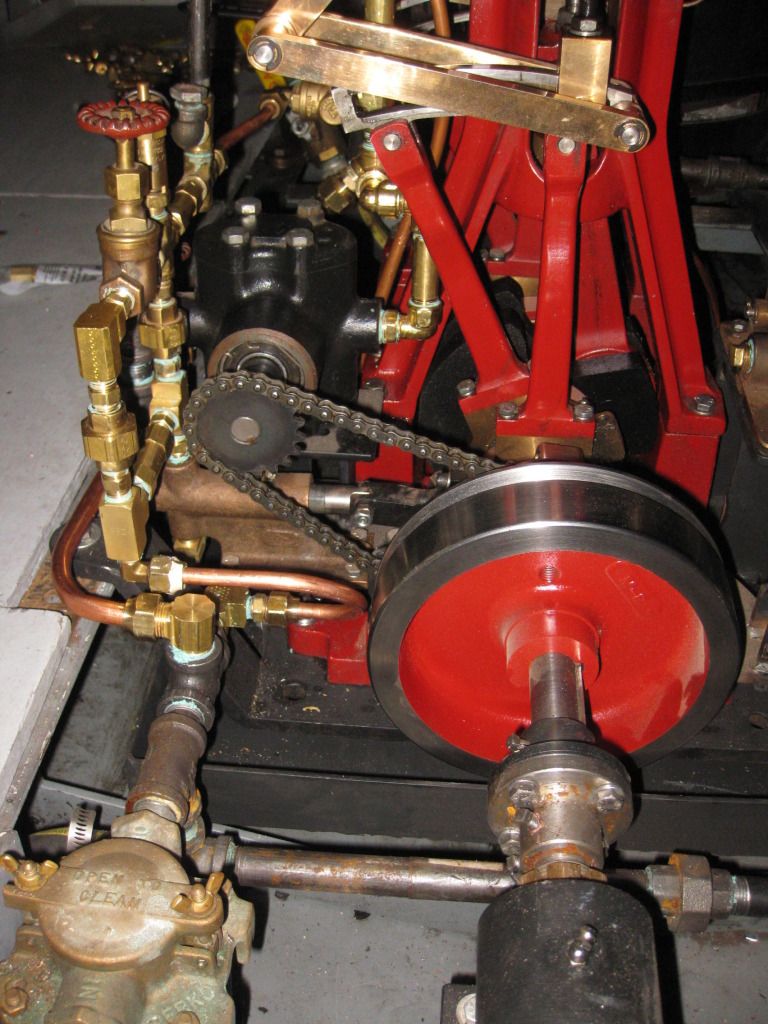

Here are the two pumps installed and piped.

If one fails, just open it's bypass and throw the 3-way valve and close the other bypass.

WARNING: These two pictures may cause dizziness..

Here is the port wheelhouse door. It's made in two sections, a brass bolt in the middle holds then together to act as one door or undo the bolt and open the window section only. And too, those are lift off hinges I made. The doors can be removed easily.

-Ron

Re: DetroiTug's Tug is going together

Posted: Tue May 22, 2012 4:01 am

by farmerden

I'm really dizzy now! I've been going round in circles!! Are both pumps wet all the time? Are both pumps working all the time? Both pumps feeding the boiler at the same time? Can you easily disconnect a pump from the engine[I guess remove the chain on one and undo the bolt in the other. My concern is that neither pump should run dry. Or in my dizzyness did I miss something?

Den

Re: DetroiTug's Tug is going together

Posted: Tue May 22, 2012 2:25 pm

by DetroiTug

Den,

It is two independent pump systems in parallel. Selectable with the 3-way valve to the left in the second picture. Each pump will simply loop through the bypass. Yes they will have water all the time, and they will both run all the time.

The way these are piped is: Water simply circulates through the bypass from the discharge to the intake. When the bypass is closed, it forces water to the boiler. It would be impossible to push water to the boiler with both pumps because of the three way valve. It will only allow water in to the main feedline to the economizer from one pump at a time. This also isolates a pump that could be leaking etc.

-Ron

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 3:56 am

by artemis

DetroiTug wrote:Den,

It is two independent pump systems in parallel. Selectable with the 3-way valve to the left in the second picture. Each pump will simply loop through the bypass. Yes they will have water all the time, and they will both run all the time.

The way these are piped is: Water simply circulates through the bypass from the discharge to the intake. When the bypass is closed, it forces water to the boiler. It would be impossible to push water to the boiler with both pumps because of the three way valve. It will only allow water in to the main feedline to the economizer from one pump at a time. This also isolates a pump that could be leaking etc.

-Ron

Whatever happened to K.I.S.S. ?

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 4:11 am

by farmerden

K.I.S.S. preluded to boredom.

However I wonder if these two aforementioned pumping systems fail,perhaps we could introduce an electric pump run off of that fancy alternator!! And then throw in the old manual pump! Den

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 8:19 am

by dhic001

So the water in the pump that isn't being used is circulating within itself? What happens when that water eventually boils? What seals are your pumps using, and how hot can they get before they get cooked?

Daniel

DetroiTug wrote: Water simply circulates through the bypass from the discharge to the intake. -Ron

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 2:20 pm

by DetroiTug

DetroiTug wrote:Whatever happened to K.I.S.S. ?

Ron, I'm setting this up for extended cruising, 2-3 day trips, hence the freshwater storage, gray tanks, generator, berths(to be added) etc. Some redundancy in a vital system like feedwater supply is a good idea, I think. And it was really quite simple to set up.

-Ron

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 2:22 pm

by DetroiTug

farmerden wrote:K.I.S.S. preluded to boredom.

However I wonder if these two aforementioned pumping systems fail,perhaps we could introduce an electric pump run off of that fancy alternator!! And then throw in the old manual pump! Den

Den, I won't have to do that, I'll just run the Southworth vertical steampump that is also being added in the future.

-Ron

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 2:26 pm

by DetroiTug

dhic001 wrote:So the water in the pump that isn't being used is circulating within itself? What happens when that water eventually boils? What seals are your pumps using, and how hot can they get before they get cooked?

Daniel

Hmmm, hadn't thought of that. Will water boil because it's simply being recirculated through a pump and bypass? I can see there being friction/heat created by the sliding surfaces within the pump, but the water would cool running through the tubing which would act as a radiator?? Or am I wrong in thinking that?

-Ron

Re: DetroiTug's Tug is going together

Posted: Wed May 23, 2012 7:18 pm

by fredrosse

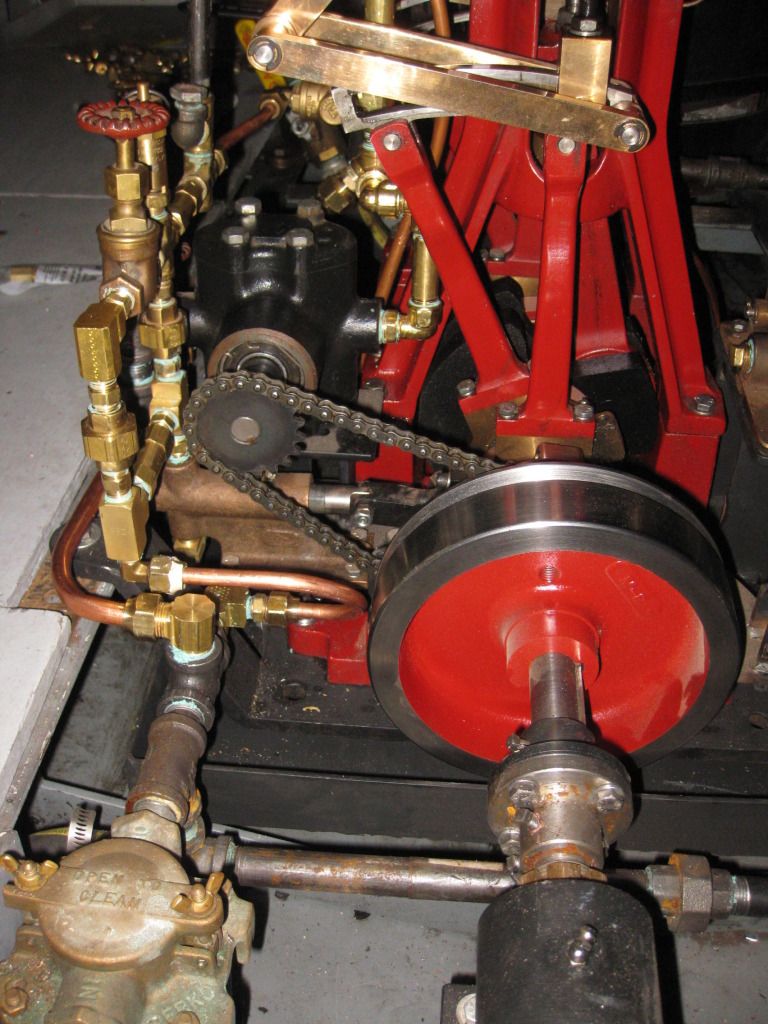

All of the work (horsepower) energy put into the shaft of the pump shows up as heat in the recirculation fluid circuit. The relevant thing here is the energy input to the circuit, compared to the ability to take away this energy by heat transfer to whatever cools the system.

For a Hypro pump in recirculation (not really producing any pressure, and not using much power), the input energy is small, and the pipes and pump casing exposed to the atmosphere provides enough cooling so that there will be no significant heating for your installation. My Hypro pump is rated for 140F maximum temperature, and it would be difficult to get even 1F temperature rise in the pump with ordinary recirculation circuit.

On large power plant feedwater pumps this is a very relevant issue, where 15,000 horsepower is put into a pump that is a couple of feet in diameter and a few feet long. These pumps typically heat up the water about 10F-15F per second, and if a healthy flow is not maintained, temperatures destroy the pump very quickly. The attached picture shows a 15,000 horsepower boiler feed pump, with big nuts holding it together. I put a $$bill in the picture for scale, don't think I have a socket wrench big enough for those.