Page 3 of 4

Re: Building a Three Drum Watertube Boiler

Posted: Wed Dec 22, 2010 6:22 pm

by Johnlanark

Casing loosely assembled with the aft end panel cutouts done. They are for the steam drum, two mud drums, feedwater heater header to starboard, superheater header to port, and fire door.

John

Re: Building a Three Drum Watertube Boiler

Posted: Wed Dec 22, 2010 7:36 pm

by farmerden

Hey John It's Christmas!It's OK to slow down and go buy some stocking stuffers for the lady who allows you to work all the time in your shop

But that being said -The boiler's coming together very nicely! Den

Re: Building a Three Drum Watertube Boiler

Posted: Sat Jan 15, 2011 3:02 pm

by Johnlanark

Slowed down for a while, as instructed by Den. I've now bought ceramic insulation board and vermiculite firebrick. Loosely assembled the casing to cut these to size, and cut out the top panel for the inner funnel starter.

John

Re: Building a Three Drum Watertube Boiler

Posted: Sun Mar 06, 2011 5:14 pm

by Johnlanark

An earlier picture showed the drum stays protruding through the end plates and retained with dome nuts. As mentioned, a drawing popped through the email from John King suggesting an improved arrangement using sleeve nuts with low profile hexes. They are aluminium bronze to resist corrosion and have a longer thread to compensate for the weaker material. They will be sealed with dowty washers. This arrangement will give more clearance for fittings on the drum end, which can be a bit tight on this type of boiler. It is rather a rolls royce upgrade - the material cost was £120 for the 12 nuts. But it will look good.

An ebay seller made up a rolled alloy tube to form the outer funnel. The joint is not “joggled” as I had ideally hoped, but will just overlap. The outer will be spaced out from the stainles flue pipe inner by bolts and spacers. A brass band at the top will be nice.

Most builders will fabricate the fire door, but I have started patternmaking for a door and surround to be cast in iron.

Door frame with hinges on the port side and keeper on the starboard.

Door outside

Door inside with bosses for heat deflector bolts. The perimeter has a thickening , which will be grooved for a fabric seal.

John

Re: Building a Three Drum Watertube Boiler

Posted: Mon Mar 14, 2011 1:33 pm

by Midship

Hello

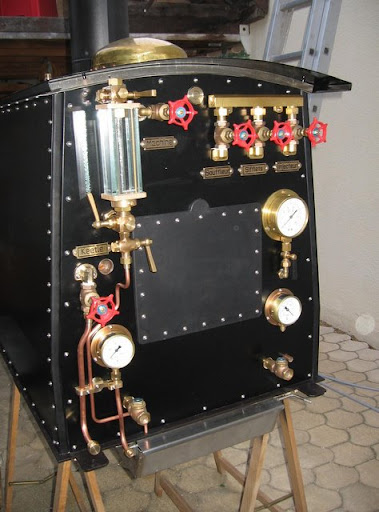

If ever you are interested, I could send you details on our réalisation

for my steamboat Midship

kind regards

midship

Re: Building a Three Drum Watertube Boiler

Posted: Mon Mar 14, 2011 7:57 pm

by farmerden

Please post more pictures Midship! That boiler interests me very much Den

Re: Building a Three Drum Watertube Boiler

Posted: Mon Mar 14, 2011 9:19 pm

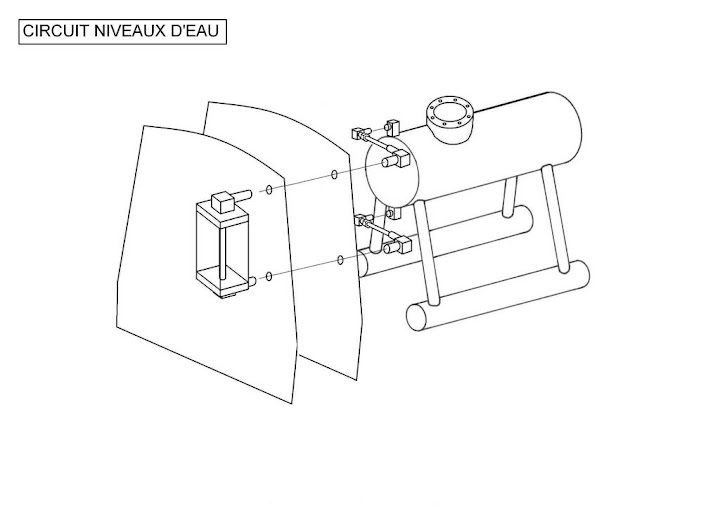

by Midship

Re: Building a Three Drum Watertube Boiler

Posted: Mon Apr 11, 2011 5:12 pm

by Johnlanark

Wonderful boilers, Midship, thanks for the photos!

My own folded ashpan did not work. It would not fold up properly to the underside of the base without distorting. However a reference from a friend has introduced me to Calum Sommerville, who has a steel and woodwork heritage fabrication business

http://www.csrestorationservices.co.uk

Calum made a new ashpan, with an angle welded to the top for a bolted connection below the baseplate. This is 2mm mild steel, and can be unbolted and renewed when it is worn out. He has also welded up the casing and the stub inner funnel. Next job is to weld a section below to mount the boiler on to the beds at the right height. It looks quite at home in the boat. You can see the low roof height of my boat shelter and why the funnel has to be detachable.

The sheet metal work was holding me up - I didn’t really want to do it anyway - but this new contact has the job progressing forward well again.

John

Re: Building a Three Drum Watertube Boiler

Posted: Tue May 17, 2011 7:16 pm

by Johnlanark

Progress on the boiler- all by Calum Somerville, none by me. Door and frame made, mud drums welded in, starter tube and flange for the outer funnel, removable side panels for access to tubes, and a handrail added on the port side. Channel section mounting welded on. The end panel at the door end has distorted with all the heat - it is specified as 1.2mm but to any other builder Calum suggests 2mm would be better. Some remedial work is needed.

The steam drum is a loose sliding fit into the casing, and insulation packing will seal round the ends. A welded on ring of 1.2mm steel provides a seating. The door has a groove inside for a seal between it and the frame protrusion.

Should have bought a bigger trolley to build it on! John.

Re: Building a Three Drum Watertube Boiler

Posted: Tue May 17, 2011 10:38 pm

by 87gn@tahoe

Beautiful little boiler. I would love to build one like this some day.

FYI: When welding sheetmetal in cases such as this or on classic cars, it helps to use a MIG or TIG welder and make many very small tack welds on alternating sides, allowing time to cool (some use a pressurized air stream to cool). It takes a lot longer and will seem like forever, but in the end there will be much less "remedial" work.