Page 16 of 16

Re: And Now for the Twin

Posted: Mon Mar 15, 2021 5:12 pm

by Mike Rometer

I have not been idle! (Well not very anyway).

- Eccentrics (1) (600 x 450).jpg (56.47 KiB) Viewed 68428 times

The bearings arrived nearly a week earlier than expected.

So where to start, sheaves or straps? I seem to have material for both, so it really doesn't matter. Straps it is then.

- Eccentrics (2) (600 x 450).jpg (57.2 KiB) Viewed 68428 times

10mm M.S. plate, four pieces. In some ways I would have preferred brass but 10mm is NOT cheap, and it wasn't in stock! I thought about Dietrich, and doing them in one hit, but discretion said, do it in two. I don't trust the stiffness of the mill with such a long cutter. Just call me windy!

- Eccentrics (3) (600 x 450).jpg (80.28 KiB) Viewed 68428 times

I hate the swarf that comes off the cutter when doing these side on cuts, it is just millions of tiny needles, I'm still picking them out of places I didn't know I had places!

Re: And Now for the Twin

Posted: Mon Mar 15, 2021 5:43 pm

by Mike Rometer

- Eccentrics (5) (600 x 450).jpg (70.15 KiB) Viewed 68420 times

I don't know how many of you will still be using one of these. I do, and love it. It is so versatile. Set up, switch on and leave it whilst getting on with something else, in this case on the lathe. When the note changes, just add a cut, change the direction, and return to what you were doing, seconds later. It doesn't remove metal that quickly, just in big chunks each stroke, it can also gives an excellent finish with light cuts.

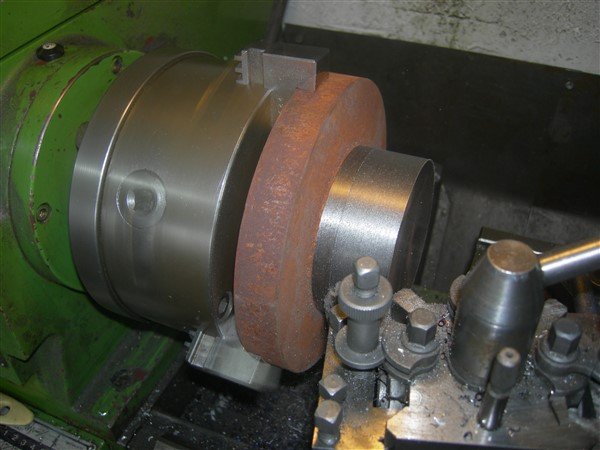

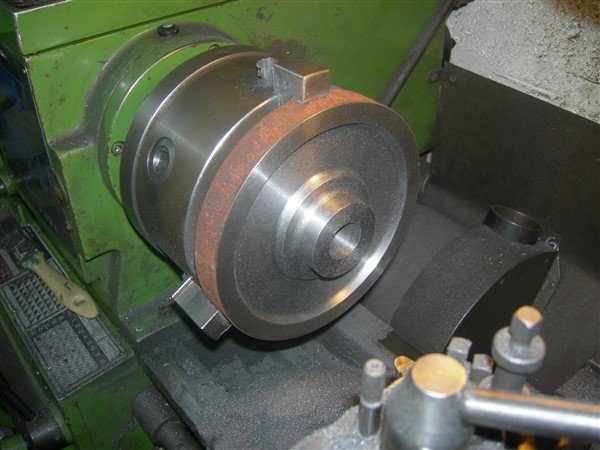

- Eccentrics (7) (600 x 450).jpg (58.64 KiB) Viewed 68420 times

To set up in the chuck I use the small piece of pipe laying on the cross-slide, as a spacer, that gives me a grip of about 3mm (1/8") but ensures a true setting. These will be bored and counter-bored on this same setting, before reversing to clean off the back. Why do them with the internal jaws? Just to make sure I have clearance from the jaws when passing through the bore.

- Eccentrics (8) (600 x 450).jpg (56.38 KiB) Viewed 68420 times

I have now busted the 400 hours.

Re: And Now for the Twin

Posted: Sat Mar 27, 2021 12:14 pm

by Mike Rometer

Not much explanation needed here, except perhaps to say the delay was enforced domesticity again. Just removing metal as quickly and safely as possible.

- Eccentrics (12) (600 x 450).jpg (60.07 KiB) Viewed 68347 times

The step at the back is 2mm thick, and will be back to back with it's pair. There will be a similar step on the outsides of the sheaves

- Eccentrics (11) (600 x 450).jpg (57.9 KiB) Viewed 68347 times

All four completed and bearings fitted. There was a little bit of a faux pas with the last one I took out a couple too many tenths and the bearing isn't as tight as I would like. Easy sort for the job, not so easy for my pride, I thought I was doing so well!

- Eccentrics (13) (600 x 450).jpg (63.27 KiB) Viewed 68347 times

I then made a dummy sheave to test the clearances on the bed-plate as I had a niggling (unfounded) worry that it might have to be returned to the mill and have more clearance added. Whilst the shaft is out again I wanted to find the exact locations for the pillars (6 off) , when I had a thought, would they be better in a straight line or with the centre pair out of line either in or out? Would that add stiffness (or just look plain wrong!)?

Re: And Now for the Twin

Posted: Sat Mar 27, 2021 1:10 pm

by DetroiTug

I ran shapers off and on for a long time, a 16,22 and 24 inch hydraulic. Great for roughing out forming dies. If ya take one of them chips down the shirt collar first thing Monday morning, it'll get ya right for the whole week.

We always put the vise end towards the wall for that reason.

I had a 16" Cincinnati in my shop for many years and finally got rid of it as it wasn't used much after we got a few CNC mills. Sold it on Ebay, some yokel showed up from 700 miles away to pick it up with a dual axle trailer, we set it on there and the bed sank all the way to the axles. He made it home surprisingly.

Ron

Re: And Now for the Twin

Posted: Sat Mar 27, 2021 1:31 pm

by Mike Rometer

That's just a baby Ron, only 8" Boxford, but a little cracker!

You still have to watch out for the chips though.

Re: And Now for the Twin

Posted: Mon Mar 29, 2021 4:39 pm

by Mike Rometer

Another slight change of direction! I've been thinking about a flywheel. As has been said before, a twin shouldn't need a large one and there is always the screw helping things along. Usual 03.00 o'clock epiphany, I've got a 6" Chuck back-plate casting sat on a shelf, very unloved, for more years than I care to count (or think about)! I dragged it out (not at 03.05) and set to and reduced the boss to a more suitable dimension.

- Flywheel (1) (600 x 450).jpg (50.64 KiB) Viewed 68300 times

Someone had already been over it and removed the crust, so a reasonable, if dirty, job. Drilled and bored and recessed it.

- Flywheel (3) (600 x 450).jpg (60.21 KiB) Viewed 68300 times

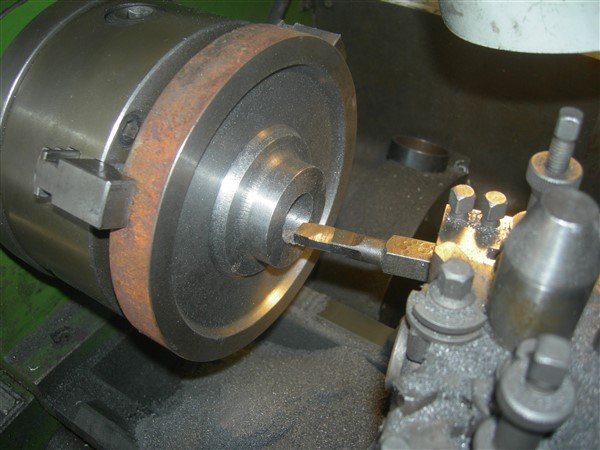

This is my method of cutting an internal keyway, I never seem to need to cut many so it's simple and still reasonably quick, and saves the cost of broaches. Grind a tool to the correct width and with a cutting face. Lock the chuck. Set the tool on centre height and adding a few thou at a time push it through the bore with the saddle, til you have the right depth (measure with a vernier).

- Flywheel (4) (600 x 450).jpg (55.37 KiB) Viewed 68300 times

Re: And Now for the Twin

Posted: Mon Mar 29, 2021 4:46 pm

by Mike Rometer

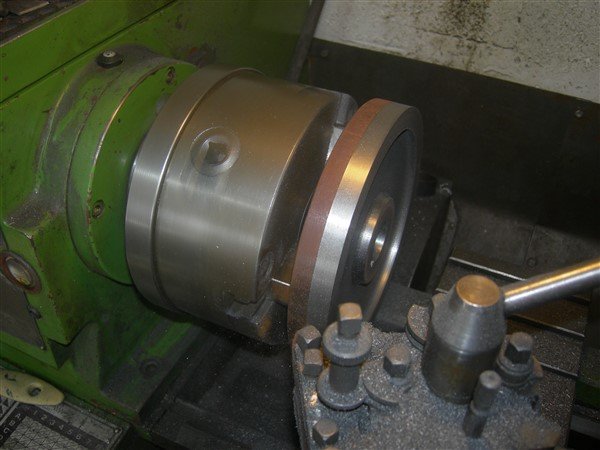

Turn it round and do the other side. The rim is 0.875" Ish wide and the recesses are about 0.250", so still plenty on the web.

- Flywheel (5) (600 x 450).jpg (49.08 KiB) Viewed 68295 times

Just the key itself to cut.

- Flywheel (6) (600 x 450).jpg (67.79 KiB) Viewed 68295 times

Another job ticked off the list. It's getting closer to the time when I'll HAVE to do the pillars, I've been putting them off because they are height critical, but I think I have a solution.

Re: And Now for the Twin

Posted: Wed May 26, 2021 4:43 pm

by Mike Rometer

I suppose you missed me? I'm afraid I got a bit waylaid by a pretty young lady,

- MG TD 1953 (600 x 399).jpg (90.73 KiB) Viewed 67941 times

She turned up on my driveway one lunchtime and I didn't have the heart to turn her away. Unfortunately she's turned out to be a bit of a hussy, as since she got here she's been dropping engine oil and Dot 4 all over the place!

I think I've sorted out the worst of her woes (for now), but you know what these girls are.

I have done a little to the twin, made a few studs and the like, and it has now had a trail assembly to check clearances and adjust for the optimum pillar length.

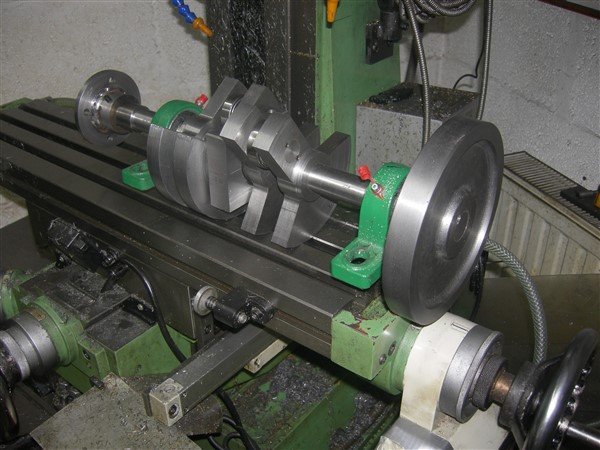

- Trial Assembly (2) (600 x 450).jpg (57.32 KiB) Viewed 67941 times

The crank feels very smooth when rotated by the rods. The cylinders are very tight and I may take a couple of thou off the pistons if I decide that is the cause. Small clearances are good, but too tight is as bad as too loose. No rings are yet fitted.

- Trial Assembly (3) (600 x 450).jpg (62.04 KiB) Viewed 67941 times

Re: And Now for the Twin

Posted: Wed May 26, 2021 5:03 pm

by DetroiTug

Lookin' good.

Re: And Now for the Twin

Posted: Fri May 28, 2021 7:05 pm

by tandemcompound

I am slowly building the single