Next Weekend II

-

87gn@tahoe

Re: Next Weekend II

I was never on the Oceanid, but have been intimately close to a HSL steam plant that we almost bought from the Windermere Steamboat Museum back in 2004. Unfortunately shipping fees plus unknown possibility of customs fees and possible limbo in customs, we ended up having to pass. It was going to be for the "Next Weekend II" I think my father would certainly be interested in another shot at owning a HSL plant, especially one with such significance in the hobby steam community.

The Oceanid's plant wouldn't be as much overkill as the Burma Queen's though. I rode on the Burma Queen back in 1997 during fleet week whilst she was still in Oakland, CA. There were a couple tugboat crew members that rode with us who were being trained for the tow up to the PNW, Jerry Ross wanted them to be able to fire her up and run her in case of emergency.

If the boiler with the Burma Queen's machinery is the original boiler is the original one that was on here when I was aboard, then the only useful pieces of machinery are the engine, auxiliaries, and the fittings and burner off of the boiler.

My father and I are not very fond of the valve gear on the BQ's compound. We're more Stephenson link kinda guys.

I have a video of that trip on the BQ. I am setting up a video capture device so I can get it onto my computer and upload the video to YouTube.

The Oceanid's plant wouldn't be as much overkill as the Burma Queen's though. I rode on the Burma Queen back in 1997 during fleet week whilst she was still in Oakland, CA. There were a couple tugboat crew members that rode with us who were being trained for the tow up to the PNW, Jerry Ross wanted them to be able to fire her up and run her in case of emergency.

If the boiler with the Burma Queen's machinery is the original boiler is the original one that was on here when I was aboard, then the only useful pieces of machinery are the engine, auxiliaries, and the fittings and burner off of the boiler.

My father and I are not very fond of the valve gear on the BQ's compound. We're more Stephenson link kinda guys.

I have a video of that trip on the BQ. I am setting up a video capture device so I can get it onto my computer and upload the video to YouTube.

- artemis

- Full Steam Ahead

- Posts: 465

- Joined: Wed Nov 18, 2009 4:13 am

- Boat Name: Pond Skimmer

- Location: Portland, Oregon, USA

- Contact:

Re: Next Weekend II

The boiler available from Jerry is "new". That is to say it is a Scotch (wetback) built in the 1950s (I think) for back up to an installation somewhere in WA state. It was tested once each year for the State Boiler Inspector until the unit was decommissioned around 2000(?). Nothing wrong with it, just time to move on. Jerry bought it back in about 2004. Buy the boiler/engine/aux from Jerry and trade the engine for Oceanid's. At that price you can't go wrong.

-

87gn@tahoe

Re: Next Weekend II

You sir, are a baaad influence

- artemis

- Full Steam Ahead

- Posts: 465

- Joined: Wed Nov 18, 2009 4:13 am

- Boat Name: Pond Skimmer

- Location: Portland, Oregon, USA

- Contact:

Re: Next Weekend II

Just carrying on with the "dirty ole man" tradition. It certainly should be applied to hobby steamboating.87gn@tahoe wrote:You sir, are a baaad influence

-

87gn@tahoe

Re: Next Weekend II

Small update:

My father did a test run of the boiler, a duplex pump, and the "gen set" in the driveway this fall with great success. He made a simple little (REALLY little, just the right size for my boat little) vaporizing burner for fun and got steam up in 45mins just playing around with it. I think with the ample grate area and a simple wood fire, steam in 20 minutes or less is easily attainable.

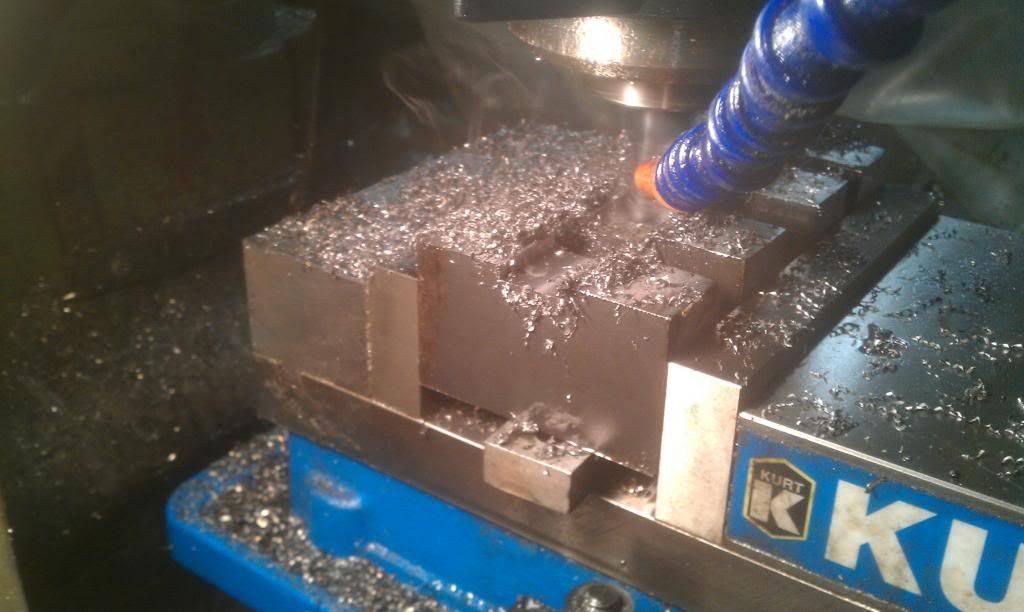

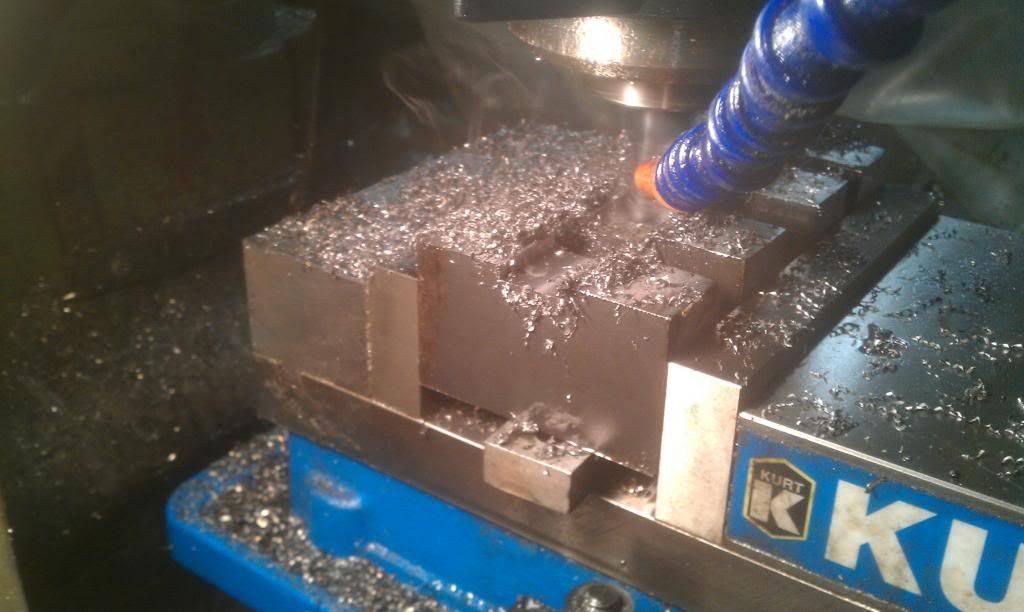

We machined (ROUGH!) up some blocks for mounting the twin feed pumps (1" ram x 3" stroke x2) to the side of the condensate pump for the Doty compound. The condensate pump is a weldament (pictured and mostly tacked together at the moment). I will be a bucket type. due to the original pump design and location in relation to the exhaust and the jet condenser (now to bee keel condenser) he had to route the exhaust in a ring around the pump. Not the most efficient method, but functional we hope.

He has also started on the headers for the condenser, using 1" dielectric union in conjunction with the copper pipe to prevent unwanted corrosion.

Fun fact: On the Doty compound, HP piston and rod assembly weighs 55lbs. The LP "hollow" piston and rod assembly weighs in at a featherweight 78lbs! Time for an aluminium LP piston me thinks.

My father did a test run of the boiler, a duplex pump, and the "gen set" in the driveway this fall with great success. He made a simple little (REALLY little, just the right size for my boat little) vaporizing burner for fun and got steam up in 45mins just playing around with it. I think with the ample grate area and a simple wood fire, steam in 20 minutes or less is easily attainable.

We machined (ROUGH!) up some blocks for mounting the twin feed pumps (1" ram x 3" stroke x2) to the side of the condensate pump for the Doty compound. The condensate pump is a weldament (pictured and mostly tacked together at the moment). I will be a bucket type. due to the original pump design and location in relation to the exhaust and the jet condenser (now to bee keel condenser) he had to route the exhaust in a ring around the pump. Not the most efficient method, but functional we hope.

He has also started on the headers for the condenser, using 1" dielectric union in conjunction with the copper pipe to prevent unwanted corrosion.

Fun fact: On the Doty compound, HP piston and rod assembly weighs 55lbs. The LP "hollow" piston and rod assembly weighs in at a featherweight 78lbs! Time for an aluminium LP piston me thinks.

- Lopez Mike

- Full Steam Ahead

- Posts: 1903

- Joined: Wed Dec 07, 2011 6:41 am

- Boat Name: S.L. Spiffy

- Location: Lopez Island, Washington State, USA

Re: Next Weekend II

Wes, you are just bent on getting your self in trouble with this aluminum stuff. (This coming from an aircraft and motorcycle guy!)

I don't think you will be able to save much weight by using aluminum in places like pistons. Most large pistons are cone shaped so that they are limited by modulus rather than tensile strength. The ratio of modulus of elasticity to weight is remarkably constant amongst most common structural materials. Steel (iron), aluminum, wood. Most of the things we deal with and design around will fail from flexing rather than just being pulled apart.

If you can figure out how to keep the piston from rubbing on the bore, it could work. Make sure the rings bottom out in their grooves before the piston can touch the cast iron perhaps? Sounds bogus as I type it. Might work though as, unlike an automotive piston, there are minor side loads.

My Strath Steam engine has an aluminum connecting rod but has bronze bearings at each end. That's the beauty of iron on iron. It puts up with comically poor lubrication.

Mike

I don't think you will be able to save much weight by using aluminum in places like pistons. Most large pistons are cone shaped so that they are limited by modulus rather than tensile strength. The ratio of modulus of elasticity to weight is remarkably constant amongst most common structural materials. Steel (iron), aluminum, wood. Most of the things we deal with and design around will fail from flexing rather than just being pulled apart.

If you can figure out how to keep the piston from rubbing on the bore, it could work. Make sure the rings bottom out in their grooves before the piston can touch the cast iron perhaps? Sounds bogus as I type it. Might work though as, unlike an automotive piston, there are minor side loads.

My Strath Steam engine has an aluminum connecting rod but has bronze bearings at each end. That's the beauty of iron on iron. It puts up with comically poor lubrication.

Mike

If you think you are too small to make a difference, try sleeping with a mosquito.

Dalai Lama

Dalai Lama

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: Next Weekend II

There are conical pistons, but I would not be surprised if this engine used a two or three part rectangular cross section LP with the center machined out to reduce weight. You could design an LP with a cast iron edge and a two part aluminum center, hollowed out with radial stiffening ribs. The trick here to change the design to use material more efficiently, rather than to simple replicate the existing design in a lighter (and less stiff) material. You can probably get away w/ a all aluminum LP piston given the condensation that will help lubricate it, but why risk it? if you need to shave weight, build a composite piston.

- Bart

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

-

87gn@tahoe

Re: Next Weekend II

The original piston is 10" diameter and 3" thick with a rectangular cross section, two-piece "hollow" (not much) design. I'm not a metallurgist, nor an engineer, but I think it would take many more cycles at 250rpm than I have the life span for to worry about exceeding the flexible life span of aluminium on a piece that thick.. Correct me if I'm wrong of course.

A solid aluminium piston would weigh around 23lbs (.098 lb/in3) Reducing the weight further by making it hollow with radial ribs whilst still retaining rigidity is appealing to me. The current LP weighs 33lbs and the HP 10lbs, so it has quite a way to go to make all things equal.

Do you really think galling will be an issue with a LP piston, possibly hard anodized, in that wet steam environment in addition to either steam cylinder oil or colloidal graphite? Like you stated Mike, there is minimal side loading.

A solid aluminium piston would weigh around 23lbs (.098 lb/in3) Reducing the weight further by making it hollow with radial ribs whilst still retaining rigidity is appealing to me. The current LP weighs 33lbs and the HP 10lbs, so it has quite a way to go to make all things equal.

Do you really think galling will be an issue with a LP piston, possibly hard anodized, in that wet steam environment in addition to either steam cylinder oil or colloidal graphite? Like you stated Mike, there is minimal side loading.

- Lopez Mike

- Full Steam Ahead

- Posts: 1903

- Joined: Wed Dec 07, 2011 6:41 am

- Boat Name: S.L. Spiffy

- Location: Lopez Island, Washington State, USA

Re: Next Weekend II

If I were to try to save weight, I would follow the ideas that Bart put forward. Maybe build a two piece aluminum piston with a cast iron hoop trapped between the two aluminum disks. The ring grooves would then be in the iron hoop.

Or possibly bolt the iron hoop to an aluminum piston center.

At the low rpm you are running this thing, the inertia loads from the piston probably aren't that big of a problem. It did run for years with the iron piston. Does the crank have balance weights? On I.C. engines the percentage of balance can be played with to 'tune' the engine to it's surroundings.

The percent of balance is worked out by adding up all of the parts that go up and down, like the piston, rod and cross head, and adding in part of the weight of the con rod. You hang the con rod horizontally and weigh the end that goes to the cross head. This total is deemed to be the reciprocating mass.

The amount to the balance to be added to the crank in excess of what will balance the bare crank is usually about 70% of the reciprocating mass. This can vary up to 10% either way. Trial and error. What you are doing is converting some of the up and down vibration to side to side vibration. If you balance to 100%, it all becomes side to side. With zero balance, the engine jumps up and down. Some where in between is the compromise that helps the problem.

This is the situation for a single cylinder engine. With a multiple cylinder engine it gets interesting. An opposed twin can be set up to have it all pretty much balance out. With a vertical twin, there are several configurations. To get reliable starting, we steamers almost always set the cranks at 90 degrees. In theory, this can make things better.

Considering the number of older engines out there in long service with no balance weights at all, it would appear that I'm over thinking the problem. In other words, keep the old piston on the shelf just in case the boats shakes your fillings loose with a different piston!

Mike

Or possibly bolt the iron hoop to an aluminum piston center.

At the low rpm you are running this thing, the inertia loads from the piston probably aren't that big of a problem. It did run for years with the iron piston. Does the crank have balance weights? On I.C. engines the percentage of balance can be played with to 'tune' the engine to it's surroundings.

The percent of balance is worked out by adding up all of the parts that go up and down, like the piston, rod and cross head, and adding in part of the weight of the con rod. You hang the con rod horizontally and weigh the end that goes to the cross head. This total is deemed to be the reciprocating mass.

The amount to the balance to be added to the crank in excess of what will balance the bare crank is usually about 70% of the reciprocating mass. This can vary up to 10% either way. Trial and error. What you are doing is converting some of the up and down vibration to side to side vibration. If you balance to 100%, it all becomes side to side. With zero balance, the engine jumps up and down. Some where in between is the compromise that helps the problem.

This is the situation for a single cylinder engine. With a multiple cylinder engine it gets interesting. An opposed twin can be set up to have it all pretty much balance out. With a vertical twin, there are several configurations. To get reliable starting, we steamers almost always set the cranks at 90 degrees. In theory, this can make things better.

Considering the number of older engines out there in long service with no balance weights at all, it would appear that I'm over thinking the problem. In other words, keep the old piston on the shelf just in case the boats shakes your fillings loose with a different piston!

Mike

If you think you are too small to make a difference, try sleeping with a mosquito.

Dalai Lama

Dalai Lama

-

87gn@tahoe

Re: Next Weekend II

The engine does have counterweights. With them the crank itself is currently close (without putting it on a balancing machine) to neutral.

My understanding of balancing an engine stems from automotive practice, where one tries to get all of the reciprocating parts to the same weight before balancing. Also any unnecessary reciprocating mass is power wasted. Hence my obsession with trying to get the LP the same as the HP, or close. We're not shooting for perfection to .001 grams or high rpms, but I would think that any effort to make things same, or similar, would help with vibration as well as bearing and crank life. The LP already has to carry the burden of the condensate and feed pumps. Reducing the weight of the LP assy by 23lbs to the HP's 55lbs couldn't hurt right?

I wont be messing with the counterweights on the original crank, as I do not think they can be removed and I'd hate to alter it too much. Maybe someday when we hit the lotto we'll make a new crank; hardened journals, gun drilled, cross drilled for forced lube, balanced etc. An all out race piece ya know

Sad thing is, I've given it quite a bit of thought... Just a hot rodder at heart. I just like beating my -organ- in a door trying to make slow things fast... Like my Buick Special Wagon; friend and I made a sheetmetal intake and I'm going to go with EFI and a 74mm ball bearing turbo.

Back to the important hobby;

What percentage does one shoot for the bobweights on a 90* crank?

My understanding of balancing an engine stems from automotive practice, where one tries to get all of the reciprocating parts to the same weight before balancing. Also any unnecessary reciprocating mass is power wasted. Hence my obsession with trying to get the LP the same as the HP, or close. We're not shooting for perfection to .001 grams or high rpms, but I would think that any effort to make things same, or similar, would help with vibration as well as bearing and crank life. The LP already has to carry the burden of the condensate and feed pumps. Reducing the weight of the LP assy by 23lbs to the HP's 55lbs couldn't hurt right?

I wont be messing with the counterweights on the original crank, as I do not think they can be removed and I'd hate to alter it too much. Maybe someday when we hit the lotto we'll make a new crank; hardened journals, gun drilled, cross drilled for forced lube, balanced etc. An all out race piece ya know

Sad thing is, I've given it quite a bit of thought... Just a hot rodder at heart. I just like beating my -organ- in a door trying to make slow things fast... Like my Buick Special Wagon; friend and I made a sheetmetal intake and I'm going to go with EFI and a 74mm ball bearing turbo.

Back to the important hobby;

What percentage does one shoot for the bobweights on a 90* crank?